ALWA EPF 10 System

Please select the quantity you need and then select below the number of components you want or need to buy.

Amount needed:

Corresponds to:

Contains:

Thixotropic

Thixotropic

Black

Black

Curing at room temperature

Curing at room temperature

Temperature resistance of 130 ° C

Temperature resistance of 130 ° C

ALWA EPF 10 System

ALWA EPF 10 is a temperature-resistant, steel-filled gelcoat based on epoxy resin. It is used to produce temperature and abrasion resistant surfaces for vacuum, PU foam, thermionic moulds and heating plates, among others.

Processing

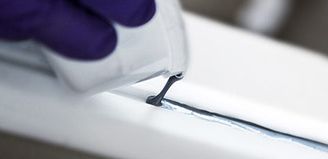

Since ALWA EPF10 is a steel-filled gelcoat, it must be mixed homogeneously before use. For this purpose, the whole container (or depending on the amount several containers) should be heated to about 40 ° C and mixed vigorously until a homogeneous liquid mass is obtained. Now the required quantity in portions of max. 1.5 kg can be weighted. More than 1.5 kg per portion can shorten the pot life. Before adding the hardener, homogenize the mass again. After that, the required amount of hardener can be stirred in carefully. The optimum processing temperature here is between 30 °C – 35 °C. In this temperature range, the pot life is shortened a little, but the material is easy to spread and can be applied to the pattern without inclusion of air. After the hardener has been stirred in, the mass is again transferred to a new container and stirred again. This serves the purpose to leave not well mixed gelcoat on the sides and on the bottom of the cup, since it would not get fully hard. The gelcoat can then be applied with a short-hair brush or a spatula (approx. 2.7 kg/m²). Please note that these steps must be done promptly one after the other, otherwise the filler will sink again and/or the gelcoat will become cold again and cannot be processed well.

If the thickness of the layer should be more than 1 mm, the mixture must be applied several times. Before the second layer can be applied, the first layer must be gelled. After the second layer of surface resin has been applied, it is either immediately sprinkled with ALUMINIUM GRANULATES (2 – 4 mm) (for mechanical bonding of the ALWA MOULD D backfilling compound) or stabilized by an epoxy laminate, epoxy backfilling or epoxy laminating paste.

Layers, which have cured, need to be grinded before continuing. In this case, it is necessary to use a copper layer, for example, of ALWA EPF 10. After curing the surface is easily machinable.

Mixing ratio

| Mixing ratio | Parts by weight |

|---|---|

| ALWA EPF 10 | 100 |

| Hardener H 10 | 5 |

Packages

| System | Unit (kg) |

|---|---|

| ALWA EPF 10 | 5 |

| Hardener H 10 | 1 |

Characteristics

| Resin / Hardener mixture | Weight | Unit | ALWA EPF 10 / Hardener H 10 |

|---|---|---|---|

| Appearance | thixotropic | ||

| Pot life at 23 °C | 500 g | min. | approx. 60 |

| Demoulding time | hrs. | 12-14 | |

| After curing and tempering of 1 hour at 120 °C | |||

| Weight | ISO 1183 | g/cm³ | approx. 3 |

| Temperature resistance | IS/R 75 | °C | 125-130 |

| Compressive strength | N/mm² | 130-140 |

Shelf life

Resin and hardener have a minimum storage life of 1 year. The products must be dry and stored at 18 °C – 25 °C in the closed original container. Resin components which are crystallised due to the storage or transport at lower temperatures can be turned back into the liquid form at a temperature of approx. 50 – 70 °C without any loss of quality. When the material is melted, the resin must be cooled down again and must have a temperature lower than 40 °C before the hardener can be stirred in.

| Characteristic | Unit | ALWA EPF 10 | Hardener H 10 |

|---|---|---|---|

| Appearance | Visual | paste | liquid, yellowish |

| Colour | black | transparent | |

| Viscosity | mPa s | 600.000 – 800.000 | 100-200 |

| Density | g/cm³ | 3,21 | 1,0 |

We are here for you!

Phone: +49 2562 98157

E-Mail: info@alwa.de

ContactMonday to Thursday

8 am - 5 pm

Friday

8 am - 2 pm