ALWA MOULD P, 200 kg

ONLY AVAILABLE AS BUNDLE

Click here to go to the bundleALWA MOULD P, 200 kg

ALWA MOULD P, 200 kg| Application: | Air film control technology, Molds for the ceramics industry, Vacuum clamping technology |

|---|

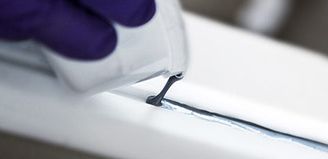

Model preparation

Die zu behandelnden Oberflächen müssen vollständig sauber sein (fett- und staubfrei).

a) Build up the model on the base plate. Porous models (e.g. PU foam) must be filled.

b) Absorbent surfaces (e.g. wood, plaster) are sealed with varnish (do not use acrylic varnish!).

Processing

The room and model temperature should be between 17 - 20 °C, otherwise the pot life will change.

| Application example no. 1 | Batch quantities < 10 kg | ||

|---|---|---|---|

| Target: Average pore diameter of ~ < 10 µ | The resin is mixed homogeneously with water. | This mixture is homogeneously stirred into the filler at a rotational speed of approx. 700 - 1000 for approx. 90 sec. | After homogeneously mixing resin and filler, the casting compound must be poured within 5 min. |

| Target: Average pore diameter of ~ < 20 µ | The resin is mixed homogeneously with water. | This mixture is homogeneously stirred into the filler at a rotational speed of approx. 550 for approx. 70 sec. | After homogeneously mixing resin and filler, the casting compound must be poured within 5 min. |

| |

|

|

| Application example no. 2 |

Batch quantities > 10 kg | ||

|---|---|---|---|

| Target: Average pore diameter of ~ < 10 µ | The water is homogeneously mixed with filler (approx. 60 sec.). | The resin is immediately added to the mixture at a rotational speed of approx. 415 for approx. 90 sec. | After homogeneously mixing resin and filler, the casting compound must be poured within 5 min. |

| Target: Average pore diameter of ~ < 20 µ | The water is mixed homogeneously with filler (approx. 60 sec.). | The resin is immediately added to the mixture at a rotational speed of approx. 485 for approx. 70 sec. | After homogeneously mixing resin and filler, the casting compound must be poured within 5 min. |

| |

|

|

We recommend mixing the total mixture in one bucket for approx. 55 sec. and then transferring one half to a second bucket. Continue stirring both mixtures according to the residual stirring time.

Downloads

Product brochure:

CAST RESIN FOR THE CERAMIC INDUSTRY ALWA MOULD P

Technical data at RT

| Property | Unit | Value |

|---|---|---|

| Processing temperature of the mixture | °C | 15 – 16 |

| Glass transition temperature | °C | ca. 100 |

| Reaction temperature | °C | < 65 |

| Density according to DIN 1306 (filled with water) | kg/l | 1,05 |

| Storage stability at 16 °C to 22 °C (do not store below 12 °C) | Monate | 6 |

| Total porosity of the mold | % | 28 – 32 |

| Average pore diameter | µ | 7 – 22 |

Calculation of the batch quantity

Calculate the casting volume in liters. To compensate for watering losses, we recommend increasing the preparation volume by approx. 5 %.

| Product | Part Number | Parts |

|---|---|---|

| ALWA MOLD P | 2000 | 20 |

| Filler | 2720 | 52 |

| water | 28 |

Container

| Product | Unit Packing | Verpackung |

|---|---|---|

| Resin | 5 | can |

| 25 | hobbock | |

| 50 | barrel | |

| 200 | barrel | |

| Filler | 10 | bucket |

| 50 | cardboard drum |

We are here for you!

Phone: +49 2562 98157

E-Mail: info@alwa.de

ContactMonday to Thursday

8 am - 5 pm

Friday

8 am - 2 pm