ALWA MOULD SLV System

Please select the quantity you need and then select below the number of components you want or need to buy.

Amount needed:

Corresponds to:

Contains:

ALWA MOULD SLV System

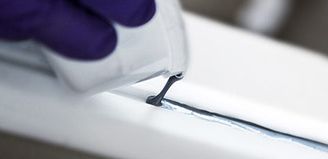

ALWA MOULD SLV is a universal two-component fast casting PU resin for mould making. It is used for the production of milling devices, negatives, product holders, foundry moulds, mould plates, copy moulds, core boxes, pattern plates, casting moulds, prototype parts, supporting moulds and synthetic cast. It consists of a beige-brown low viscosity resin component A (polyol mixture) and a red-brown, low viscosity hardener (component B) based on isocyanate (Methylendi(phenylisocyanat)e = MDI). Two types are available with different pot life:

ALWA MOULD SLV 3 ~ 3 min. pot life

ALWA MOULD SLV 9 ~ 9 min. pot life

| Application: | Milling jigs, support molds, control casts, copy molds, negatives |

|---|

Packages

| System | Unit (kg) | Package |

|---|---|---|

| Resin | 5 | Can |

| Resin | 25 | Can |

| Filler | 25 | Bag |

Shelf life

Storable for up to 12 months in a closed package at room temperature. Opened containers must immediately be re-sealed tightly.

Processing

Caution: Component A must be stirred or shaken prior to use. In the processing of filler, it needs to be added carefully to both components before the components are mixed together. Briefly vent the finished mixture and immediately cast it into the dry patterns that have been carefully pre-treated with release agent. Porous patterns (e.g., wood) have to be sealed before the release agent is applied.

Layers of ALWA MOULD SLV which are cast in intervals of 5 min. on top of each other interconnect well. In order to cast thicker layers (over 20 mm) up to 300 key weightings of filler can be added on 100 key weightings of resin and 100 key weightings of hardener. In order to reach a better mould accuracy, a quantum of 200 key weightings of filler should not be exceeded. Aggressive solvents, such as benzene, white spirit and turpentine substitute are not recommended for cleaning of the cured mould material.

Example:

5 kg ALWA MOULD SLV, Comp. A + 5 kg ALWA MOULD SLV, Comp. B + 7,5 kg (1.5 times more) filler white or beige

or:

ALWA MOULD SLV, Comp. A = 28,57 %

ALWA MOULD SLV, Comp. B = 28,57 %

Filler white or beige = 42,86 %

Protective measures

The hardener component contains isocyanate. Therefore, it may irritate skin, eyes and respiratory tract and sensitise skin and respiratory tract for chronic exposure as well as cause allergic reactions. For allergic persons and persons who are prone to respiratory diseases the processing is not recommended. Safety goggles, safety gloves and suitable working clothes should be worn whenever working with these substances. Pay attention to cleanliness at the workplace and make sure that the work space is thoroughly ventilated. Keep skin and eyes protected. Avoid open fire. Dab at accidental splatters on the skin and remove them with soapy water. In case of splashes in the eye, rinse out the eyes for 10 – 15 min. and consult a doctor. In addition, the following points have to be considered or requested before processing:

- Safety data

- Hazard warnings and safety advice on the containers

- Information sheet M 044 of BG Chemie: Production of polyurethane/isocyanate (Source: Verlag Chemie GmbH, Weinheim/Bergstraße)

The product is water-polluting in its liquid state or when it is not fully cured and, therefore, must not be drained into the sewage system, water or soil. In any case, leftovers must be disposed properly.

| Technical data | SLV 3 approx. 3 min. pot life | SLV 9 approx. 9 min. pot life |

|---|---|---|

| Resin component A (polyol) (colour) | beige | milky beige |

| Resin component B (isocyanate) MDI (colour) | brown | yellowish-brown |

| Mixing ratio (parts by weight) | 100:100 | 100:100 |

| Density of the mixture (g/cm³) | 1,1 | 1,1 |

| Hardness (shore D) | ~ 70 | ~ 68 |

| Viscosity of the unfilled mixture at 21 °C (mPa s) | ~ 50 | ~ 150 |

| E-module (N/mm²) | 1100 | 1100 |

| Impact strength (Kj/m²) | ~ 15 | ~ 12 |

| Bending strength (MPa) | ~ 55 | ~ 41 |

| Temperature resistance ASTM (°C) | ~ 60 | ~ 60 |

| Processing time at 20 °C (min.) | ~ 3 | ~ 9 |

| Demoulding time at 21 °C (min.) | ~ 45 | ~ 210 |

| Linear shrinkage after 7 days (with filler 1 : 2; specimen 500 x 25 x 20 mm) (%) | ~ 0,2 | ~ 0,2 |

| Reaction temperature (unfilled, according to the film thickness) (°C) | > 80 | > 80 |

Three fillers can be used. The selected filler defines the mechanical characteristics.

| Art. no. of the filler | Characteristic | Addition max. in % |

|---|---|---|

| 8510025 | Filler – easily machinable, white | ~ 150% |

| 8511025 | Filler – easily machinable, beige | ~ 150% |

| 4065025 | Aluminium filler | ~ 150% |

We are here for you!

Phone: +49 2562 98157

E-Mail: info@alwa.de

ContactMonday to Thursday

8 am - 5 pm

Friday

8 am - 2 pm