ALWA SIL SH System

Application:

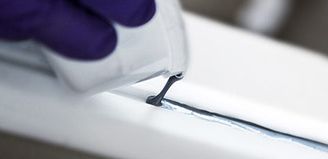

silicone impression

Product number:

SW10007

Attention this product is a bundle!

Please select the quantity you need and then select below the number of components you want or need to buy.

Please select the quantity you need and then select below the number of components you want or need to buy.

Amount needed:

kg

Corresponds to:

1

Volume in kg

Contains:

Component A: 0,5kg

Component B: 0,5kg

Flexible casting moulds

Flexible casting moulds

Copy moulds

Copy moulds

Moulds with undercuts

Moulds with undercuts

Polyurethane casting moulds

Polyurethane casting moulds

Concrete casting moulds

Concrete casting moulds

Product information "ALWA SIL SH System "

ALWA SIL SH System

Silicone rubber ALWA SIL SH 22 and SH 33 are silicone impression materials. These materials have extremely high mechanical values. In addition, they are very fast to handle and very easy to handle as well.The two-component silicone rubbers cure at room temperature. After mixing the two components, a low viscosity liquid develops, which crosslinks to a resistant and rubber elastic material. During the crosslinking, no exothermic heat is developed. When 1 – 3 % thixotropic agent is added per component, a spreadable mixture is obtained.

| Application: | Foundries |

|---|

| Characteristic | SH22 | SH33 |

|---|---|---|

| Silicone type | Addition | Addition |

| Hardness (shore A) Test time: after 12 hours Test specimen: 65 x 65 x 6 mm |

~ 20 – 25 | ~ 30 – 35 |

| Mixing ratio (%) | 100:100 | 100:100 |

| Colour | Blue | Translucent, red, blue, green |

| Pot life at 20 °C – 22 °C (min.) | ~ 18 – 25 | ~ 20 – 25 |

| Time to demoulding at 20

– |

~ 1 – 2 | ~ 2 – 3 |

| Viscosity (mPa s) | ~ 3.500 ± 1.000 | ~ 4.500 ± 1.000 |

| Tear-strength (kgf/cm) | ~ 18 – 31 | ~ 11 – 17 |

| Tensile strength (kgf/cm²) | ~ 45 – 75 | ~ 60 – 90 |

| Elongation (%) | ≥ 400 | ≥ 350 |

| Shrinkage (%) | ≤ 0.1 | ≤ 0.3 |

| Temperature resistance (°C) | ~ 220 | ~ 220 |

We are here for you!

Phone: +49 2562 98157

E-Mail: info@alwa.de

ContactMonday to Thursday

8 am - 5 pm

Friday

8 am - 2 pm