In-House Moldmaking

Patented Casting Resin System for Producing Sophisticated Thermoforming Molds in just a Few Hours

Patented Casting Resin System for Producing Sophisticated Thermoforming Molds in just a Few Hours

Compared with conventional thermoforming molds made from epoxy resins or aluminum, a new type of casting resin system not only enables heat-resistant and high-quality thermoforming molds to be produced in a much shorter time, but the user can make the molds himself. The system can also serve as an alternative to injection molding to achieve a favorable price-performance ratio.

Synthetic Resin versus Aluminum

In industry, synthetic resins, especially those based on polyurethane and epoxy, have long since become established for the manufacture of tools for the vacuum thermoforming process (e. g. construction industry, automotive industry, furniture industry, mechanical engineering, sports and leisure industry). Both positive and negative molds can be cast.

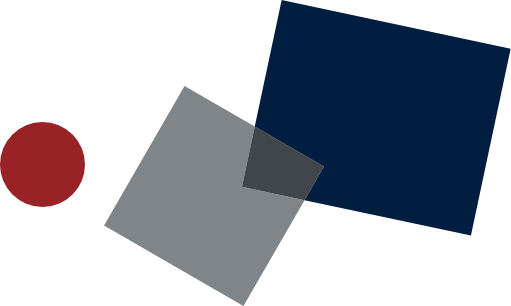

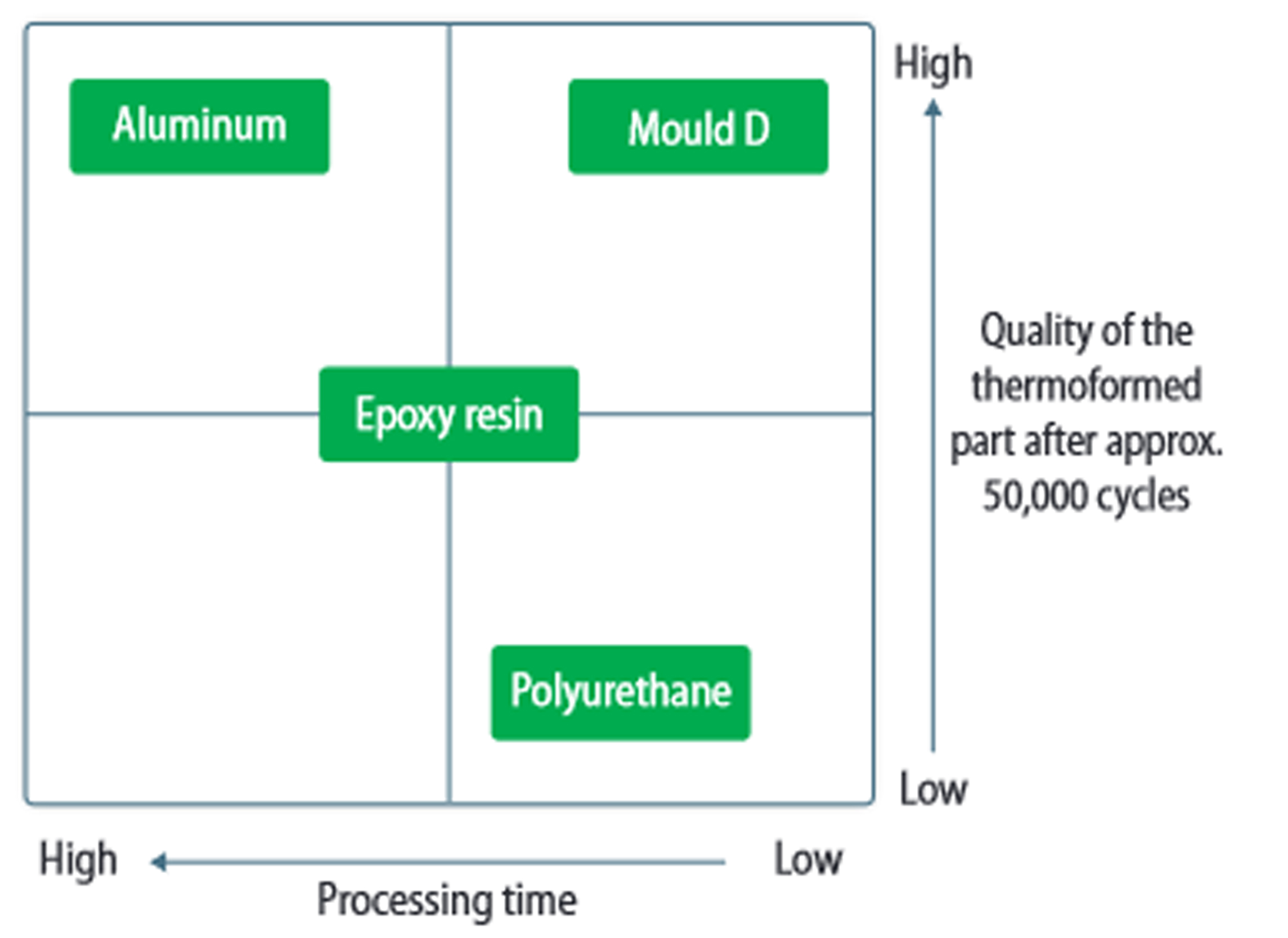

Molds made from polyurethane casting resin offer the user a cheap, rapid solution for the production of negative molds. The disadvantages are shrinkage and inferior mechanical properties (e. g. strength and heat deformation resistance). For their part, epoxy casting resins have the advantage of less odor formation, less shrinkage and comparatively better mechanical properties. Their disadvantages are time-consuming production and the necessary post-curing before the mold can go into service. Moreover, the process is unsuitable for the production of larger molds, as stress cracks form in the mold after only a few thermoforming operations (Fig.1).

Polyurethane and epoxy resins are often only used for producing prototypes and small production series, whereas aluminum molds are the first choice for medium and large runs, due to their better mechanical properties, albeit they come at a higher cost and longer delivery times. Aluminum molds are capable of high production volumes because they have very good thermal conductivity and heat resistance, which permit fast cycles, and they have a long service life.

.jpg)

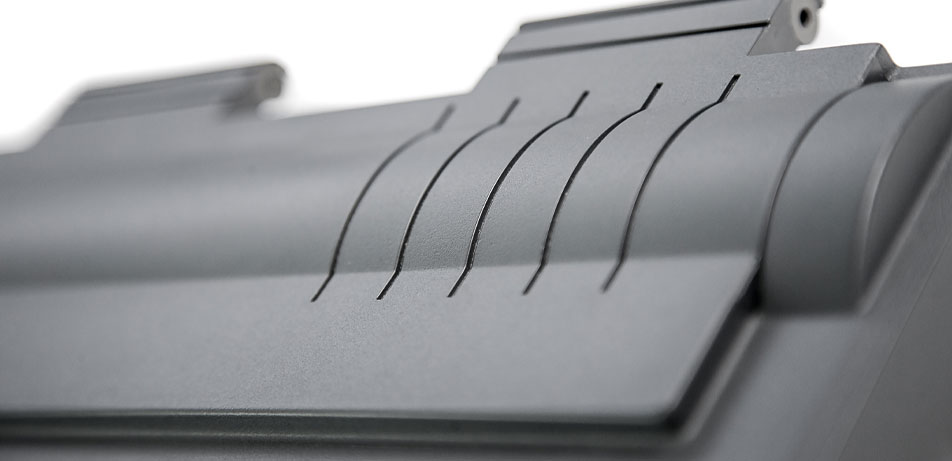

Fig. 1. Comparison of materials: Mould D is quick to process and a match for aluminum in terms of quality.

Aluminum molds are typically CNCmilled or cast. However, milling a solid material is time-consuming and costintensive and aluminum casting, for its part, is usually carried out of house in a foundry. Casting resins not only offer economic advantages, but also allow molds to be produced in-house at short notice.

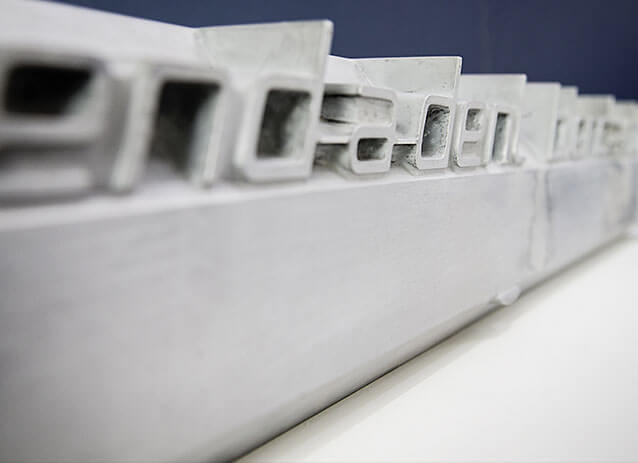

This gap has been closed by a patented casting resin system with very good mechanical properties. The casting resin, Mould D, meets users’ needs in terms of processability, strength and range of applications and has unique selling points that distinguish it from conventional materials. The advantage of Mould D (Title figure) is that, after a waiting time of just 1 to 2 hours, a ready-to-use, fully utilizable production mold is available that meets high production requirements without the need for additional post-curing. This opens up the door to low-cost, very high-quality molds produced in-house.

About the product ALWA Mould d

Fig. 1. Comparison of materials: Mould D is quick to process and a match for aluminum in terms of quality.

Aluminum molds are typically CNC- milled or cast. However, milling a solid material is time-consuming and cost- intensive and aluminum casting, for its part, is usually carried out of house in a foundry. Casting resins not only offer economic advantages, but also allow molds to be produced in-house at short notice.

This gap has been closed by a pat- ented casting resin system with very good mechanical properties. The casting resin, Mould D, meets users’ needs in terms of processability, strength and range of applications and has unique sell- ing points that distinguish it from con- ventional materials. The advantage of Mould D (Title figure) is that, after a waiting time of just 1 to 2 hours, a ready-to-use, fully utilizable production mold is avail- able that meets high production require- ments without the need for additional post-curing. This opens up the door to low-cost, very high-quality molds pro- duced in-house.

About the product

Saving on drilled vacuum holes:

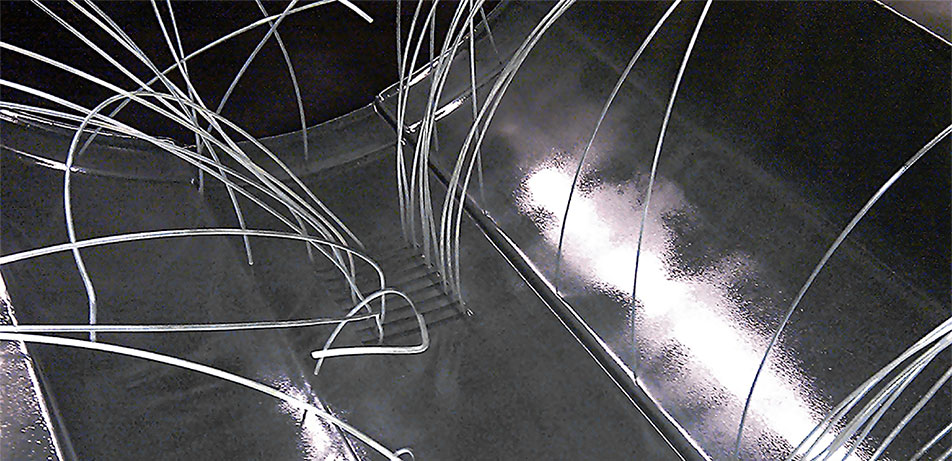

where a vacuum is to be applied in the thermoforming mold later, silicone-sheathed steel wires used during pattern preparation keep the cavities open during casting

Comparison with Aluminum Molds

Mould D has several advantages over aluminum molds milled from solid ma terial: a mold can be cast in just a few hours and be placed on the thermo forming machine immediately after de molding. The use of silicone-coated steel wires during casting avoids the need for time-consuming drilling of vac uum holes in the mold (Fig. 2). In addi tion, pipes to heat and cool the mold are also cast in the pattern to provide tem perature control during production runs (Fig. 3). Due to the resin’s mechanical properties and simple scalability, even very large molds can be produced (e. g. 2500 kg).

In the case of aluminum molds, and especially large ones, the high thermal conductivity leads to uneven heat dissi pation, with the result that in particular the edges often cannot be thermoform ed without optical defects. In contrast, Mould D molds dissipate heat more evenly due to their lower thermal con ductivity, yielding optically perfect thermoformed parts with uniform film stretching (Fig. 4). The only time alumi num is preferable to its reaction resin counterpart is in the case of high-speed molds, because it permits faster cycle times and high production numbers (100,000 to 150,000) on account of its better thermal conductivity and greater heat resistance.

The material costs of aluminum molds are particularly high when the molds have cavities and accordingly a large amount of aluminum chips are generated during their manufacture. By contrast, casting in Mould D permits a displacer to be used, which not only saves on mold material, i. e. reduces resin consumption, but also reduces weight.

Design changes can be imple mented in just a few hours, compared with the time-consuming casting and repairing aluminum molds. In addition, molds made from synthetic resin are ea sier to mill than their aluminum counter parts. With Mould D, it is possible to achieve 100 % molding accuracy and, by maintaining the given temperature, to achieve non-shrink casting (Table 1), with the result that a 1:1 copy of the pattern is always produced.

Shrinkage-free casting of Mould D

| Properties | Unit | Value |

|---|---|---|

| Casting temperature | °C | 21 |

| Reaktionsspitzentemperatur | °C | 126 |

| Pot life | min | 17 |

| Boost | mm | 1,2 |

| Boost/shrinkage open potting | mm | +/- 0 |

Design changes can be implemented within a few hours, while casting and repairing aluminum molds prove to be very time-consuming. In addition, resin molds are easier to mill than aluminum. With Mould D, one hundred percent molding accuracy can be achieved and, if the temperature is maintained, casting is shrinkage-free (Table 1), so that a 1 : 1 copy of the model is always produced.

Thermoforming or Injection Molding?

Thermoforming is an economical alter native to injection molding. Since less pressure is built up in thermoforming, the mold can be made from much cheaper materials. The cost of a thermoforming mold is about one-tenth that of an injec tion mold. Further advantages are that both large molds and molds of complex geometry can be thermoformed. The choice of processing method ul timately depends on the complexity and size of the mold, the production volume and costs, delivery time and material em ployed. On account of the high level of surface detail and because undercuts can be made with the aid of aluminum slide molds, thermoformed parts produced with Mould D are comparable in quality to injection molded parts.

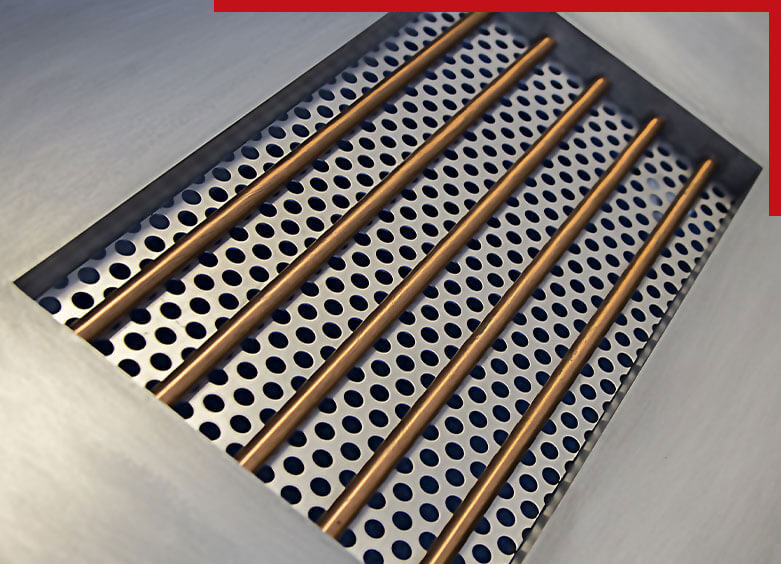

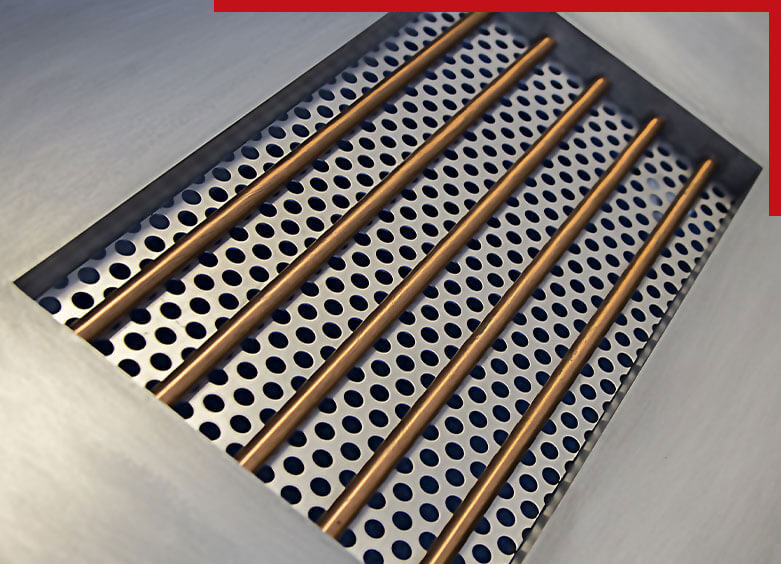

Preparing for Pattern Casting

Almost all pattern materials are suitable for casting (wood, gypsum, plastics, leather, metal, acrylic, etc.), with the ex ception of polystyrene. All materials must be dry. To cast the material, a casting box is built around the pattern. If mold-tem perature control is needed during the production process, copper pipes or heating elements can be placed at a dis tance of 3 to 4 cm from each other and 1 to 2 cm from the surface of the pattern. This kind of mold-temperature control usually shortens cycle times substantially during subsequent production. For this purpose, the copper pipes or heating el ements first have to be pre-bent to match the contour of the pattern (Fig. 3).

For flat and long molds, it is best to use perforated aluminum sheet as rein forcing material to avoid bending of the mold (due to the bi-metallic effect). The copper pipes or heating elements can be attached to the perforated aluminum sheet (e. g. with wires) to ensure uniform pipe spacing. Displacers made from PU foam can be used to economize on ma terial. All inserts should be spaced at least 10 mm from the pattern surface.

Time-consuming drilling of vacuum holes on the finished mold can be avoided by incorporating steel wires sheathed in silicone tubing in the pattern. Porous master patterns made of gypsum or wood have to be sealed. Each pattern is pre-treated with a surface tension rem over which ensures smooth coverage of the release coat applied afterwards, and then the steel wires sheathed in silicone tubing are inserted into the drilled 1 mm holes (Fig.2). A release coat is carefully ap plied with a brush or spray gun (at least 3 to 4 layers in the case of fine structures). The copper pipes or heating elements at tached to the perforated aluminum sheet and the displacer can now be affixed to the pattern. Drive-in nuts for better de molding or later mounting to the thermoforming machine should be in corporated into the pattern.

Cross-section of a thermoforming mold made from Mould D: the copper pipes provide temperature control and the perforated aluminum sheet is used to reinforce the mold

Cross-section of a thermoforming mold made from Mould D: the copper pipes provide temperature control and the perforated aluminum sheet is used to reinforce the mold

Preparing for Pattern Casting

Almost all pattern materials are suitable for casting (wood, gypsum, plastics, leather, metal, acrylic, etc.), with the ex ception of polystyrene. All materials must be dry. To cast the material, a casting box is built around the pattern. If mold-tem perature control is needed during the production process, copper pipes or heating elements can be placed at a dis tance of 3 to 4 cm from each other and 1 to 2 cm from the surface of the pattern. This kind of mold-temperature control usually shortens cycle times substantially during subsequent production. For this purpose, the copper pipes or heating el- ements first have to be pre-bent to match the contour of the pattern (Fig. 3).

For flat and long molds, it is best to use perforated aluminum sheet as rein forcing material to avoid bending of the mold (due to the bi-metallic effect). The copper pipes or heating elements can be attached to the perforated aluminum sheet (e. g. with wires) to ensure uniform pipe spacing. Displacers made from PU foam can be used to economize on ma terial. All inserts should be spaced at least 10 mm from the pattern surface.

Time-consuming drilling of vacuum holes on the finished mold can be avoided by incorporating steel wires sheathed in silicone tubing in the pattern. Porous master patterns made of gypsum or wood have to be sealed. Each pattern is pre-treated with a surface tension rem over which ensures smooth coverage of the release coat applied afterwards, and then the steel wires sheathed in silicone tubing are inserted into the drilled 1 mm holes (Fig.2). A release coat is carefully ap plied with a brush or spray gun (at least 3 to 4 layers in the case of fine structures). The copper pipes or heating elements at tached to the perforated aluminum sheet and the displacer can now be affixed to the pattern. Drive-in nuts for better de molding or later mounting to the thermoforming machine should be in- corporated into the pattern.

Working Steps for Casting the Model

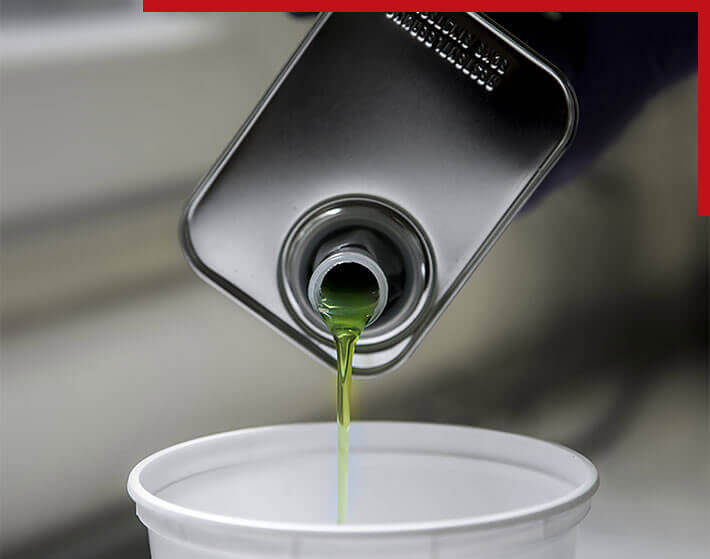

The synthetic resin system consists of a resin-filler combination of 40 parts by weight Mould D casting resin with a den sity of 1.7 kg/dm³, 60 parts by weight aluminum spray grit and 1.2 parts by weight hardener powder (3 %, expressed in terms of the casting resin content). In the first step, the two resin components are mixed with a special agitator that in troduces only a tiny amount of air into the mixture, and then the filler, an aluminum spray grit, tailored to the resin compo nents is added. The finished batch is left o stand for 1 to 2 h until air bubbles have stopped rising. For casting, the casting compound should have a tem perature between 19 °C and 22 °C. If possible, both the pattern and the am bient temperatures should also be in this range. Below 19 °C, the casting ma terial will expand so much that it will not shrink back to its original size after cool ing down while, above 22 °C, it will undergo shrinkage. The hardener powder is then carefully stirred into the casting compound over the course of 3 to 5 min.

After venting and within the pot life of approx. 17 min, the casting com- pound is poured into the prepared pat- tern in a thin stream. Some 20 to 25 min after addition of the hardener powder, the reaction sets in: the liquid resin mix- ture starts to gel and increasingly solid- ifies. Further hardening is characterized by a rapid temperature increase and reaction temperatures of up to 130 °C. This hardening characteristic permits even heat-sensitive patterns, e. g. wax patterns, to be accurately molded. The casting is completely cured by free-rad- ical polymerization about 30 minutes later. Once peak temperature has been reached, the mold starts to expand (Table 2). Therefore, the steel wires have al- ready to be pulled out quickly at approx. 80 °C as otherwise star-shaped cracks may occur around the approx. 1 mm dril- led vacuum holes. Because the mold ex- pands, the screws on the long sides of the casting box should be removed to enable it to expand properly. The mold shrinks back to its original size as it cools. Demolding can be started after the cast- ing has cooled to 80 to 100 °C.

Flat or thin molds must be clamped to a level surface while hot (immediately after hardening) and weighted down with a plate coated with a release agent or melamine resin to prevent mold ben- ding and thus the bi-metallic effect. The molds can now be easily mechanically processed (drilled, milled, ground, planed, sawn, turned). Holes can be dril- led into the mold and threads can be cut. However, it is more effective to first cast nuts or bolts into the mold. Wet grinding and the use of polishing paste produces a shiny metallic surface due to the aluminum particles in the resin. De- sign changes and small repairs to the surface can be made with a special syn- thetic resin filling compound.

Deep drawing with and without machine

If the mold is to be affixed to the base plate of a thermoforming machine, suffi ciently large holes must be drilled into the base plate to allow the Mould D mold to expand. The fixing screws must be tightened only slightly, as the mold ex pands when heated. Molds made from Mould D are suitable for continuous use at up to 135 °C. Brief exposure to the Vicat softening temperature of 180 °C (Table2) is possible, but the compressive strength of the mold will be lower due to the higher temperature.

To produce thermoformed parts without a thermoforming machine, vac uum tubes can be cast into the mold and a vacuum connection attached. A clamp ing frame is fitted around the mold to fix the plastic film. Polymer sheeting is then heated in the oven to soften it, placed on the mold and held by the clamping frame. The thermoplastic is then pre blown (or stretched). When the vacuum is applied, the thermoplastic material nestles directly against the mold. After cooling, the clamping frame can be opened, and the molded part can be re moved after a short blast of air for de molding.

Technical data of Mould D

| Properties (standard) | Value |

|---|---|

| Continuous temperature resistance | 135 °C |

| Drip time | ~17 min |

| Reaction temperature | 120 – 130 °C |

| Hardness (Shore D) | ~± D 86 |

| Compressive strength at RT 20 °C or 100 °C (DIN 53454) | 8 – 9 bzw. 7 – 8 kN/cm² |

| Impact strength (DIN 53453) | 3400 J/n (3,5 kJ/m²) |

| Mixture viscosity | ~7000 mPa·s |

| Specific density | 1,7 kg/l |

| Thermal conductivity (DIN 1341) | ~1 W/mK (~0,86 kcal/h·m·°C) |

| Linear shrinkage after curing (test specimen: 500 x 100 x 25 mm) | ~± 0,1 % |

| Vicat softening temperature (DIN 53460) | 180 °C |

| Storage stability at 16 - 22 °C | ~18 Monate |

| Coefficient of thermal expansion (DIN 53752) | 45·10–6 K-1 |

Working Steps for Casting the Model

The synthetic resin system consists of a resin-filler combination of 40 parts by weight Mould D casting resin with a den sity of 1.7 kg/dm³, 60 parts by weight aluminum spray grit and 1.2 parts by weight hardener powder (3 %, expressed in terms of the casting resin content). In the first step, the two resin components are mixed with a special agitator that in troduces only a tiny amount of air into the mixture, and then the filler, an aluminum spray grit, tailored to the resin compo nents is added. The finished batch is left o stand for 1 to 2 h until air bubbles have stopped rising. For casting, the casting compound should have a tem perature between 19 °C and 22 °C. If possible, both the pattern and the am bient temperatures should also be in this range. Below 19 °C, the casting ma terial will expand so much that it will not shrink back to its original size after cool ing down while, above 22 °C, it will undergo shrinkage. The hardener powder is then carefully stirred into the casting compound over the course of 3 to 5 min.

After venting and within the pot life of approx. 17 min, the casting com pound is poured into the prepared pat tern in a thin stream. Some 20 to 25 min after addition of the hardener powder, the reaction sets in: the liquid resin mix ture starts to gel and increasingly solid ifies. Further hardening is characterized by a rapid temperature increase and reaction temperatures of up to 130 °C. This hardening characteristic permits even heat-sensitive patterns, e. g. wax patterns, to be accurately molded. The casting is completely cured by free-rad ical polymerization about 30 minutes later. Once peak temperature has been reached, the mold starts to expand (Table 2). Therefore, the steel wires have al ready to be pulled out quickly at approx. 80 °C as otherwise star-shaped cracks may occur around the approx. 1 mm dril led vacuum holes. Because the mold ex pands, the screws on the long sides of the casting box should be removed to enable it to expand properly. The mold shrinks back to its original size as it cools. Demolding can be started after the cast ing has cooled to 80 to 100 °C.

Flat or thin molds must be clamped to a level surface while hot (immediately after hardening) and weighted down with a plate coated with a release agent or melamine resin to prevent mold ben ding and thus the bi-metallic effect. The molds can now be easily mechanically processed (drilled, milled, ground, planed, sawn, turned). Holes can be dril led into the mold and threads can be cut. However, it is more effective to first cast nuts or bolts into the mold. Wet grinding and the use of polishing paste produces a shiny metallic surface due to the aluminum particles in the resin. De sign changes and small repairs to the surface can be made with a special syn thetic resin filling compound.

Thermoforming with and without Machine

If the mold is to be affixed to the base plate of a thermoforming machine, suffi ciently large holes must be drilled into the base plate to allow the Mould D mold to expand. The fixing screws must be tightened only slightly, as the mold ex pands when heated. Molds made from Mould D are suitable for continuous use at up to 135 °C. Brief exposure to the Vicat softening temperature of 180 °C (Table2) is possible, but the compressive strength of the mold will be lower due to the higher temperature.

To produce thermoformed parts without a thermoforming machine, vac uum tubes can be cast into the mold and a vacuum connection attached. A clamp ing frame is fitted around the mold to fix the plastic film. Polymer sheeting is then heated in the oven to soften it, placed on the mold and held by the clamping frame. The thermoplastic is then pre blown (or stretched). When the vacuum is applied, the thermoplastic material nestles directly against the mold. After cooling, the clamping frame can be opened, and the molded part can be re moved after a short blast of air for de molding.

Technical data of Mould D

| Properties (standard) | Value |

|---|---|

| Continuous temperature resistance | 135 °C |

| Drip time | ~17 min |

| Reaction temperature | 120 – 130 °C |

| Hardness (Shore D) | ~± D 86 |

| Compressive strength at RT 20 °C or 100 °C (DIN 53454) | 8 – 9 bzw. 7 – 8 kN/cm² |

| Impact strength (DIN 53453) | 3400 J/n (3,5 kJ/m²) |

| Mixture viscosity | ~7000 mPa·s |

| Specific density | 1,7 kg/l |

| Thermal conductivity (DIN 1341) | ~1 W/mK (~0,86 kcal/h·m·°C) |

| Linear shrinkage after curing (test specimen: 500 x 100 x 25 mm) | ~± 0,1 % |

| Vicat softening temperature (DIN 53460) | 180 °C |

| Storage stability at 16 - 22 °C | ~18 Monate |

| Coefficient of thermal expansion (DIN 53752) | 45·10–6 K-1 |

Fields of Application

anufacturers in the sanitary industry, es- pecially in the field of bathtub and shower tray production, such as Duravit AG, Egypt, use Mould D in the production of their negative molds, because it has prov- en to be not only the most cost-efficient and fastest system, especially for medium series, but also the best system on ac- count of the quality of the thermoformed parts. CIV-Service Outillage, Chanas, France, uses Mould D in the production of electric vehicles in a thermoplastic design under the Aixam brand name. The cus- tomer appreciates the fact that all produc- tion can be done in-house. Meanwhile, by using a synthetic resin system, thermo- forming companies (such as Menschik GmbH & Co.KG, Lindlar, Germany) gain from being able to offer all processing steps from a single source.

Recent project results show that molds made from Mould D are very likely to be suitable as compression molds for forming sheet metal. Such molds could supersede the steel and sheet metal molds used up to now, and that would save companies both time and money. In- itial test results reveal that, even under a pressure of 3500t (280bar), a small mold will not be damaged during sheet metal pressing. Mould D is also suitable as a backfill compound for foam molds and RTM (resin transfer molding) molds. Some applications require a better surface quality, heat resistance and chemical resis- tance. In these cases, a metal mask of low- melting alloy is sprayed onto the pattern and then backfilled with Mould D.

Conclusion

Mould D offers a way to produce high quality thermoforming molds in a much shorter time compared with conventional moldmaking materials. It even allows users to produce demanding and large molds while conserving resources.

At K 2019, the Mould D system opened the door for new collaborative ventures, especially in the Indian market, with Machinecraft, Mumbai, Pinnacle In- dustries Limited, Pithampur, and Therm O Pack, Kanchipuram. The product is also set to be launched on the Chinese market in 2021.