ALWA POR Porous slabs and blocks

ALWA POR is entirely porous and consists of aluminum, ceramic/mineral or (chrome-)steel and a binding agent.

The surface quality is dependent on the pore diameter. Based on the specific material different applications are particularly suited. All ALWA POR products are produced in our plant in Gronau and are available as slabs or blocks. In case of ALWA POR Aluminum, different pore diameters are available. In addition to its porosity, it is characterized by its low density, good machinability, and high stability.

Moreover, a shiny surface can be created by polishing.

The properties of ALWA POR allow many applications. The following applications have been successfully implemented by our customers:

Vacuum- and thermoforming

ALWA POR Aluminum offers various advantages over traditional thermoforming tools. For example, there is no need to drill vacuum holes, because the porous material creates a homogenous airflow across the whole tool.

Therefore, imprints, deviations of wall thickness, air inclusions and other defects are avoided. This is especially important for products with high optical requirements.

In addition, the constant air permeability creates new possibilities in terms of thermoforming tool design. Complex structures are often not feasible for full-metal moulds, because the necessity of drillings limits the design flexibility. In comparison to that, moulds made from ALWA POR offer an easy machinability paired with flexible design possibilities.

The high porosity allows a fast cooling of the tool and the long-term temperature resistance of approx. 190°C enables the processing of almost all thermoplastic materials.

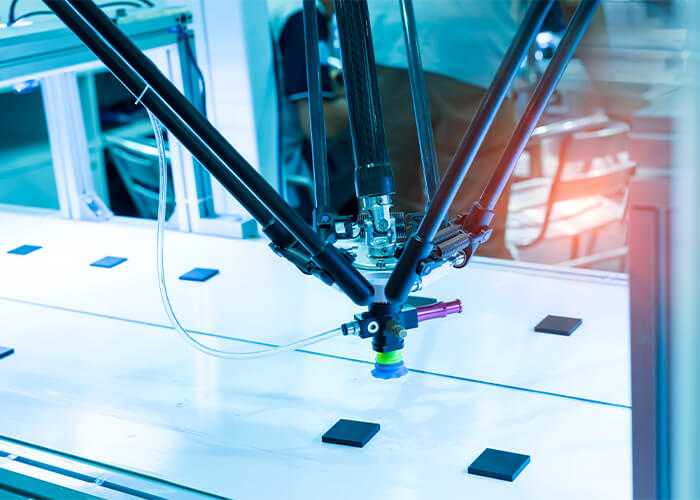

Vacuum clamping technology

ALWA POR is ideally suited for vacuum clamping technologies because of its continuous porosity. Thus, vacuum tables and vacuum plates can be produced, without the need for holes or grids to apply the vacuum.

An important advantage of ALWA POR is, that sensitive materials like thin foils, filigree parts or paper are not damaged by the fine pores.

The clamping force does even apply, when the workpiece is not covering the whole surface and can be adjusted by varying the pore diameter and the plate thickness.

Besides vacuum plates, gripper arms can be manufactured, which offer a gentle and at the same time reliable grip. This can be used in automated production processes.

About the product ALWA POR

Filter applications

The properties of ALWA POR provide perfect requirements for filter applications, while the excellent machinability allows nearly every conceivable form. It is suitable for an application in all kinds of media, such as gases, oils, or aqueous solutions. Therefore, many different purposes are possible, such as hydraulic filters, pneumatic filters, fine filters etc. Because of its porosity, the material has a high filter capacity and can easily be back flushed, which shortens and eases the cleaning process. Filters consisting of ALWA POR are of low density, form stable and can be run with higher pressure than filters made from compressed wire, ceramic, or plastic.

The filter effect can be combined with the sound suppressing effect of the material, thus pneumatic applications are highly beneficial.

Air film sliding technology

The application of classic mechanical conveyor systems, such as rolls or belt conveyors, can be a source of problems, especially for fragile materials. In comparison, ALWA POR is excellently suited for a gentle conveyance, as it allows an almost contactless transport. To achieve this, air is passed through the porous material creating a thin air film on the surface, that carries the workpiece. The transport via air film prevents damage caused by conveyance and enables a nearly effortless transport, since the workpieces are sliding on an air cushion.

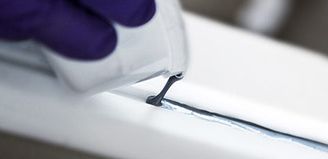

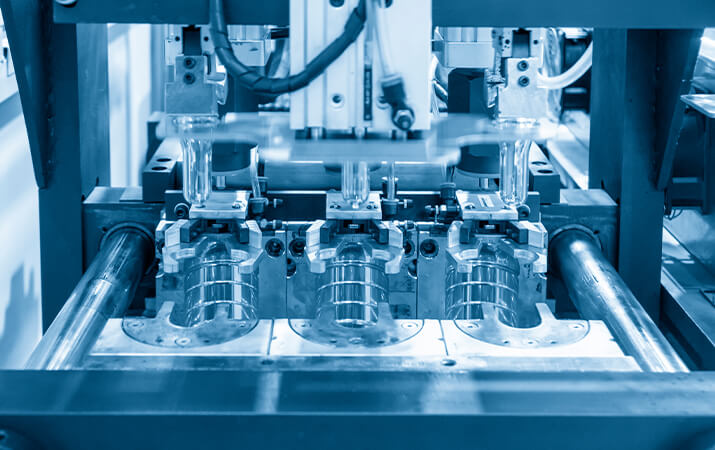

Workpiece deaeration

Various applications benefit of a preferably complete deaeration, to obtain the desired results. Key examples are blow and injection moulding. Since remaining air can cause several different material defects, the usage of ALWA POR is beneficial, especially when the requirements for the surface quality of the products are high. ALWA POR can be used to prevent these issues by installing a highly reliable deaeration.

About the product ALWA POR

Sleeve fitting in flexographic and gravure printing processes

Usually in flexographic and gravure printing processes the printing sleeves are installed onto an adapter with the assistance of pressurized air. Therefore, the adapter is perforated along its entire length. A common problem is the high consumption of pressurized air and the noise development. Alternatively, ALWA POR can be used to attach a completely breathable ring around the adapter. This enables an almost effortless sleeve installation, where the compressed air consumption and noise development are reduced to a minimum.

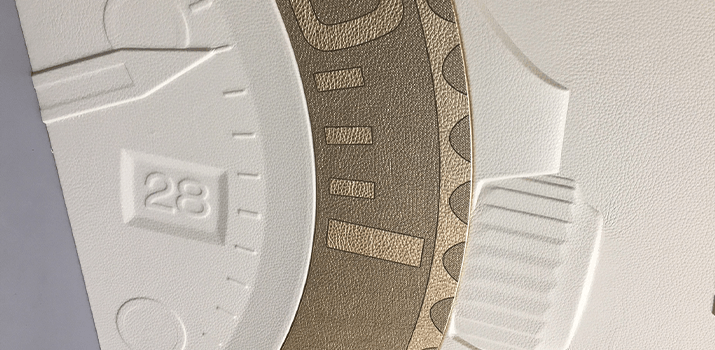

Decoration and design

Due to the high machinability of ALWA POR, various forms can be manufactured fast and precisely. Edges and patterns caused by milling maintain their shape, as the material does not crumble. Thus, fine engravings can be produced, which can be transferred to other materials such as leather true to detail. For that, the other material is tightened to the engraved ALWA POR form by applying a vacuum.

Ventilation systems

ALWA POR can be used in any application, that requires a fine gas dispersion, making the material highly promising for ventilation systems for example in fish tanks, regardless of size. Its isotropic fine-pored structure enables a constant and homogenous gas flow, independent of the design.

About the product ALWA POROther possible applications of ALWA POR

In addition, further applications, that need to be tested to assure that ALWA POR meets your specific requirements, are feasible. For this purpose, we are gladly providing samples of our material:

Pneumatic transport

The high porosity of ALWA POR, paired with its fine pore diameter, may be utilized in pneumatic conveyors such as fluid channels. These are being used to bring hardly flowable bulk material into a fluidized state. For that, ALWA POR could be installed at the bottom of the channel and be passed through by air. The air then flows around the single particles of the bulk material and annuls their adhesion between each other. Hence, the material is put into a fluidized state, that allows a very high volumetric flow rate. The fine pore diameter prevents the bulk material from entering and thus blocking the pores. Following the same functional principle, silo installations can be manufactured, that eliminate arching and ratholing.

About the product ALWA POR

Shock absorption

ALWA POR might also be suited for different shock absorption applications. It offers a higher plastic deformation compared to full metal, because of the deformation of the single pores. Therefore, the material in total absorbs a higher amount of energy. For instance, this can be utilized for filling material in parts that are used for impact protection.

Steam and hot air applications

ALWA PORs porosity facilitates a completely homogenous stream of steam and hot air, which is why it might be suited to be used in tools to produce foamed plastics such as EPS. The tool parts made from ALWA POR are flexible in design, since the material offers a good machinability paired with a constant flow throughout its entire surface.

About the product ALWA PORSilencers

In pneumatic processes compressed exhaust air is inevitably generated, which can cause a significant noise pollution. Because of its porosity, ALWA POR could be used to produce sound suppressors, that could be installed at the exhaust ports, to prevent the loud, abrupt gas expansion. The functional principle would equal the principle of suppressors made from sinter metals, such as sinter bronze, however it would miss the disadvantage that single metal granules may loosen due to the pressure and vibration stresses. ALWA POR offers an easy milling machinability, resulting in a high flexibility of the suppressor form. Accordingly, sound suppressors in various forms are manufacturable, which can be used as filters at the same time, depending on the application conditions.

Heat exchanger and cooling

ALWA POR has a very large inner surface, due to its high porosity. Accordingly, a quick heat transmission with its surrounding is possible, resulting from the large contact area. Hot solid parts in contact with ALWA POR could consequently give their heat to their surrounding more effectively. Gas flowing through ALWA POR gets heavily swirled, because of the high number of pores, and consequently has a highly accelerated heat exchange.