ALWA MOULD D BACKFILLING COMPOUND (RTM pressure injections)

Please select the quantity you need and then select below the number of components you want or need to buy.

Amount needed:

Corresponds to:

Contains:

Large volumes of more than 2500 kg can be cast in less than 45 min.

Large volumes of more than 2500 kg can be cast in less than 45 min.

Good castability

Good castability

Hardly measurable linear shrinkage

Hardly measurable linear shrinkage

High temperature resistance

High temperature resistance

Demoulding process after approx. 90 min. (after adding the backfilling compound)

Demoulding process after approx. 90 min. (after adding the backfilling compound)

Chemical adhesion to polyester or vinylester gelcoat

Chemical adhesion to polyester or vinylester gelcoat

Immediately after the first mould half has cooled down, the second mould half can be prepared

Immediately after the first mould half has cooled down, the second mould half can be prepared

Copper pipes keep the mould surface on a nearly constant temperature

Copper pipes keep the mould surface on a nearly constant temperature

Post-curing is not necessary

Post-curing is not necessary

ALWA MOULD D BACKFILLING COMPOUND (RTM pressure injections)

RTM pressure injections

Surfaces of:

- Polyester gelcoat

- Vinylester gelcoat

Foam moulds

Surfaces of:

- Polyester gelcoat

- Vinylester gelcoat

- Epoxy gelcoat

- Metal spray surface layer (zinc)

- Galvano

For example suitable for:

- Polyurethane (PU) foam injection

- Resin injection moulds

- Reaction injection moulding (RIM) / Structural reaction injection moulding (SRIM)

- PU reaction injection moulding

- PU integral foam moulds

- PU flexible foam moulds

- Glass fibre mat reinforced thermoplastics

(GMT) and fibre reinforced polymer (FRP) for prototypes and small series - Cold and hot pressure moulds up to 130 °C

| Application: | Foam molds, cold press molds, Pouring or ramming mixes, RTM pressure injections |

|---|

Preparation of the backfilling

- Calculate the complete casting volume in litres (e.g., calibration with water or sand) and multiply the amount with the density = complete quantity of backfilling.

- Bend the copper pipe over the pattern and fix it to the prefabricated casting box with a distance of 20 –

40 mm from the pattern’s surface. The pipes should have a distance of approx. 60 – 80 mm to each other. - Screw the casting box with the fixed copper pipes to the model and then begin to seal.

Processing instructions

Cast all the following mixtures with the complete filler content one by one into the first mixture until the pattern is almost full. After the last backfilling has been cast, the pure resin will settle at the surface. The placed back part of the filler of the first backfilling is mixed into this pure resin.

Next working steps

After the first mould half is cured, the following working steps can be taken:

- Building of the wall thickness (distance)

- Ventilation systems (riser)

- Building of the second mould half

Tempering

After cold curing (the reaction temperature of the backfilling can reach approx. 60 °C) the two warm mould halves will be spanned with screw clamps against each other and demoulded after cooling. Now, a water heater is adjusted to approx. 80 °C and fixed to the copper pipes. The mould surface is covered and the mould is tempered for 10 hrs. at 80 °C. In order to increase the temperature resistance of the mould it can be tempered up to 130 °C.

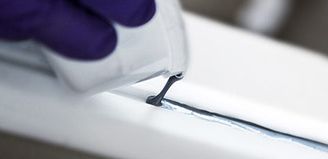

Finish of the mould surfaces

We recommend to wet grind the mould surfaces with 600 – 2000 grain and, afterwards, to polish them.

| Density of filler mixture for RTM | 2.0 kg/l |

| Viscosity | > 10000 cps |

| Linear shrinkage | < 1 mm/m |

| Temperature resistance | approx. 135 °C |

| Reaction temperature | approx. 50°C – 70°C |

| Pot life of backfilling compound at 21°C | approx. 45 min. |

Approx. 70 – 100 demouldings per release agent layer can be realised by using Frekote 700 NC.

Required materials and quantities:

| ALWA MOULD COAT (gelcoat) | art. no. 3600003 | approx. 1000 g per m² |

| ALWA HARDENER, fluid, for ALWA MOULD COAT | art. no. 3650000 | approx. 15 g per m² |

| ALWA BARRIER COAT | art. no. 3610006 | approx. 2000 g per m² |

| ALWA HARDENER, fluid, for UP gelcoat + ALWA BARRIER COAT | art. no. 3150001 | approx. 20-40 g per m² |

| Glass mat | approx. 40-80 g per m² | |

| Spin split powder-coated glass fibre mat | approx. 300 g per m² | |

| ALWA MOULD D, component 1 | art. no. 6000… | approx. 100 g per l |

| ALWA MOULD D, component 2 | art. no. 6001… | approx. 200 g per l |

| ALWA HARDENER POWDER for ALWA MOULD D / P / PERM | art. no. 5100001 | approx. 6 g per l |

| ALWA FILLER MIXTURE for RTM and PU moulds | art. no. 8530025 | approx. 1700 g per l |

| Copper pipes (soft) – 10mm | art. no. 9210000 | approx. 10 m per l |

Preparation of the pattern

The pattern should not have any undercuts and has to be clean, smooth and dry. Choose stable material for the pattern and casting box, which are suitable to carry the weight of the backfilling. Fastenings, polyurethane displacer, guide pins and loose parts of the mould have to be fixed at the pattern or the casting box before the backfilling is cast. Porous surfaces have to be sealed with ALWA ACRYLIC SEALER (art. no. 9535000). In order to achieve a high-gloss surface, the surfaces should be coated with lacquer (EP or PU lacquer) and treated with a very fine grade of wet sandpaper. ALWA SURFACE TENSION REMOVER (art. no. 9500000) is applied on the surfaces of the pattern and the casting box with a cloth in order to remove the tension of the surfaces (prevents the formation of drops when applying ALWA RELEASE LACQUER). Afterwards, ALWA RELEASE LACQUER (art. no. 9510000) is applied with a sponge, cloth or a spray gun (at least three layers). ALWA RELEASE LACQUER dries after approx. 30 – 60 min. depending on the room temperature. Hot air accelerates the drying process (e.g., by using a dryer). Errors can be avoided by using materials with similar thermal conductivity for the pattern and the casting box. Heating and cooling systems (e.g., copper pipes) should have a distance of 5 cm between each other and a distance of 2 cm to the surface. Only aluminium perforated sheets should be used as reinforcement material (2 – 3 mm). The sheets must be fixed to the pattern with a distance of 2 cm to the pattern’s surface. Please consider the different thermal conductivities when something is later attached to the mould. Once the pattern is dry, gelcoat can be applied.

Surfaces

Coat or spray polyester or vinylester gelcoat for PU foam moulds and

press moulds (layer thickness of approx. 1 – 3 mm) bubble-free on the

pattern. After the gelcoat has cured, the backfilling is cast carefully

and directly on the gelcoat layer. ALWA EPF 10 (art. no. 3300005)

(approx. 2.7 kg/m²) is preheated to 30 °C and stirred in the original

container. Afterwards, the needed quantity is taken out of the container

and mixed very well with 5 % hardener H 10 (art. no. 3310001). The pot

life is approx. 40 – 50 min. at 30 °C. ALWA EPF 10 for moulds with

abrasion-resistant surface is coated in two layers. When the first layer

is cured but still sticks at the backside, the second layer is coated

and immediately sprinkled with aluminium granulates 2 – 4 mm (art. no.

8024025) as mechanical bond of the backfilling. After the gelcoat layers

are fully cured, one can start to cast. Loose aluminium particles must

be removed before the backfilling is cast. Metal sprayed zinc surfaces

(layer thickness 1 – 3 mm) are used for RIM and other PU moulds. The

backsides of the metal spray surfaces are first coated with a thin layer

of polyester gelcoat in order to get a better bond between the metal

surface and the backfilling. Afterwards the backfilling is immediately

cast on the gelcoat, which has not yet been cured. Galvano moulds are

additionally equipped with a mechanical bond for the backfilling

compound.

- Calculate the casting volume in litre.

- Multiply the volume with the density of the compound = batch quantity in kg.

| 5 % | ALWA MOULD D comp. 1 | art. no. 6000… |

| 10 % | ALWA MOULD D comp. 2 | art. no. 6001… |

| 85 % | Filler mixture for RTM | art. no. 8530025 |

| 2 % | Hardener (2 % on the resin content) | art. no. 5100001 |

Mineral Backfill

(low viscosity mixture; in case of bigger volumes we recommend using a concrete mixer)

Mix resin and filler, add the hardener and mix for approx. 3 – 5 min. Cast the first backfilling into the deepest

part of the pattern (possibly place the pattern with the casting box diagonally). Gelcoat layer or metal mask

should be well moistened. The backfilling has a pot life of approx. 60

min. at 19 – 22 °C. The backfillings can be mixed and cast one by one.

| 5 % | ALWA MOULD D comp. 1 | art. no. 6000… |

| 10 % | ALWA MOULD D comp. 2 | art. no. 6001… |

| 55 % | Filler mixture for RTM | art. no. 8530025 |

| 30 % | 30 % of the filler mixture for RTM is deferred | art. no. 8525025 |

| 2 % | Hardener (2 % on the resin content) | art. no. 5100001 |

Additional Backfill

| 5 % | ALWA MOULD D comp. 1 | art. no. 6000… |

| 10 % | ALWA MOULD D comp. 2 | art. no. 6001… |

| 85 % | Filler mixture for RTM | art. no. 8530025 |

| 2 % | Hardener (2 % on the resin content) | art. no. 5100001 |

| Vinylester selcoat surface (ALWA MOULD COAT) | ||

|---|---|---|

| ALWA MOULD COAT (gelcoat) | art. no. 3600006 | approx. 1100 g/m² |

| ALWA hardener, fluid, for ALWA MOULD COAT (gelcoat) | art. no. 3650000 | approx. 16 g/m² |

| ALWA BARRIER COAT | art. no. 3610006 | approx. 2000 g/m² |

| ALWA hardener, fluid, for ALWA BARRIER COAT | art. no. 3150001 | approx. 20 g/m² |

| Glass mat (simple moulds, 1 x 40 g/m²) | art.no. 8611000 | approx. 40 g/m² |

| Glass mat (complex moulds, 2 x 40 g/m²) | art. no. 8611000 | approx. 80 g/m² |

| Spin split powder-coated glass fibre mat | art. no. 8610000 | approx. 225 g/m² |

| Epoxy selcoat surface (ALWA EPF 10) | ||

|---|---|---|

| EPF 10 | art. no. 3300005 | approx. 2700 g/m² |

| Hardener H10 | art. no. 3310001 | approx. 135 g/m² |

| Aluminium granulates | art. no. 8024025 |

| Polyester gelcoat surface (ALWA UP GELCOAT) | ||

|---|---|---|

| ALWA UP gelcoat | art. no. 3020006 | approx. 2000g/m² |

| ALWA hardener, fluid, for ALWA UP gelcoat | art. no. 3150001 | approx. 20g/m² |

| Glass mat (simple moulds, 1 x 40 g/m²) | art. no. 8611000 | ~ 40 g/m² |

| Glass mat (complex moulds, 2 x 40 g/m²) | art. no. 8611000 | ~80 g/m² |

| Spin split powder-coated glass fibre mat | art.no. 8610000 | ~225 g/m² |

We are here for you!

Phone: +49 2562 98157

E-Mail: info@alwa.de

ContactMonday to Thursday

8 am - 5 pm

Friday

8 am - 2 pm