Applications

| Application | Products | |

|---|---|---|

| Suction moulds and suction devices | ALWA POR | |

| Bath tubs, shower trays | ALWA MOULD D | |

| Aerators for aquariums, fish ponds and sewage treatment plants | ALWA POR ALUMINIUM | |

| Electro casting | ALWA HT RESIN | |

| Venting of injection moulding and blow moulding tools | ALWA POR STEEL | |

| Drainage and filter systems | ALWA POR | |

| Moulds for the ceramics industry | ALWA MOULD P | |

| Milling devices, support moulds, control casts, copy moulds, negatives | ALWA MOULD SLV | |

| Casting and injection moulding processes | ALWA HT RESIN | |

| Casting and ramming mixes |

ALWA HT RESIN ALWA MOULD D BACKFILLING COMPOUNDS FOR COMPACT MOULDS |

|

| Foundries |

ALWA POR ALUMINIUM ALWA SIL |

|

| Impregnating resin, prepreg, vacuum infusion | ALWA HT RESIN | |

| Air film sliding technology |

ALWA MOULD P ALWA POR ALUMINIUM ALWA POR KUNSTSTOFF ALWA POR MINERAL |

|

| RTM pressure injections |

ALWA HT RESIN ALWA MOULD D BACKFILLING COMPOUNDS FOR COMPACT MOULDS |

|

| Foam moulds, cold press moulds | ALWA MOULD D BACKFILLING COMPOUNDS FOR COMPACT MOULDS | |

| Sleeve assembly in roller printing units | ALWA POR ALUMINIUM | |

| Vacuum and thermoforming |

ALWA MOULD D ALWA POR ALUMINIUM |

|

| Vacuum clamping technology e.g. vacuum tables |

ALWA MOULD P ALWA POR ALUMINIUM ALWA POR KUNSTSTOFF ALWA POR MINERAL |

|

| Heat pumps, fitting insulation, valves, covers | ||

| Other potential applications | Products | |

| Decor and design | ALWA POR | |

| Shock absorption | ALWA POR | |

| Heat exchanger and cooling | ALWA POR | |

| Pneumatic transport e.g. in fluid channels and silos | ALWA POR | |

| Steam and hot air processes | ALWA POR | |

Filtration

Infiltration through the filters made of ALWA POR has very convincing advantages over conventional filtration materials. ALWA POR allows flexible production of filters with different porosity. By using our ALWA POR porous sheets, filter cloths in filter presses even become completely redundant. While filter cloths have to be changed every few months and the filter system thus comes to a standstill, our porous plates filter between 1 and 2 years or even longer. This means that a whole mass of filter cloths is no longer needed, which leads to a significant reduction in the amount of waste produced. With our porous plates ALWA POR a longer durability is achieved due to the high stability, a more effective filter performance due to the adjustable porosity as well as due to the higher filter resistance. Possible applications include in particular the filtration of microplastics from wastewater.

Vacuum table

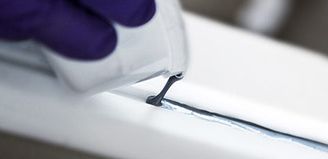

Microporous vacuum plates from ALWA allow a screwless method of fastening blanks to machining equipment. ALWA POR is the ideal solution for clamping and fixing in precision machining as well as in testing and measuring processes. Due to the porosity, deformation of the workpieces can be excluded, as no vacuum holes are necessary. Sensitive foils are thus not deformed by vacuum drilling. ALWA POR is suitable for fixing foils and electronic parts and as a mold gripper for soft bodies.