Advantages of casting resins for thermoforming moulds

Vacuum-Thermoforming, is a process for the forming of thermoplastic materials.

Benefits of casting resin for thermoforming moulds

Vacuum-Thermoforming, is a process for forming or shaping thermoplastic materials. Synthetic resins, especially polyurethane- and epoxy- based ones, are utilised in many sectors of industry (e.g. construction, vehicle manufacturing or the furniture industry) for prototype and small-scale production purposes.

Aluminium moulds, on the other hand, are preferred when large quantities are required. That is because they have better mechanical properties (good thermal conductivity and temperature stability) on the one hand, while on the other hand aluminium moulds appeal, because they have long service lives. But there are also disadvantages, because aluminium moulds are usually manufactured using CNC milling technology, which is time-consuming and expensive. Furthermore, aluminium casting is usually performed externally at a foundry.

That is exactly where we at ALWA GMBH come into play, with our patented MOULD D casting resin, because it provides the opportunity of making moulds at short notice, inexpensively and very conveniently on your own premises. A ready-to-use, entirely reliable manufacturing tool is available after a waiting time of just one to two hours – no casting resin anywhere in the world hardens faster.

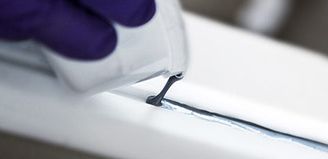

Another major benefit of our casting resin is that it is very easy to handle. That is because just two components, a filler and a hardener, need to be combined. The material is so good and easy to cast that moulds of any size can be produced. For example, our customer VST-Works used ALWA MOULD D to construct a 1200-litre hull mould featuring excellent surface quality and an elegant shape.

ALWA MOULD D benefits at a glance:

ALWA as your first point of contact for any Vacuum-Thermoforming

✓ Excellent castability with no air pockets

✓ Mechanical finishing is easily feasible

✓ Post-curing is not necessary

✓ High heat resistance

✓ Low linear shrinkage

✓ Highly accurate mould surface reproduction

✓ Steel wires can be attached, eliminating the need for time-consuming

vacuum channels

✓ Easy casting of quantities ranging from 1 kg to 2500 kg

In marketing its innovations like ALWA MOULD D, this Gronau-based family

business continuously utilises new technologies and therefore enhances

manufacturing industry. Our customers attach a great deal of importance to

premium quality deep-drawn components that they are able to produce using our

material. Sustainability has become an important issue not just in the

thermoforming segment. ‘Green’ procurement of raw materials is also a very

important concern at ALWA, to help conserve the Earth’s resources.

Do you have any questions about casting resins, deep drawing or would you like some advice? Then get in touch with us, and we will soon enable you to start producing sophisticated thermoforming tools in just a few hours – and self-built at low cost to boot.