ALWA POR STEEL

- Products

- About ALWA

- Customer service

Filter

–

ALWA POR STEEL

Here you can see all the advantages of ALWA POR (CHROM-) STAHL at a glance:

- is made of steel or stainless steel and a resin binder.

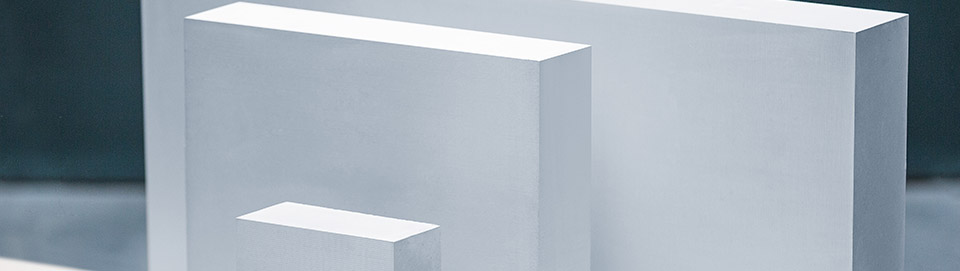

- is porous and produced as a block or slab in our factory in Gronau, Germany.

- has a good surface with good porosity.

- is suitable for injection moulds and blow moulds venting (thermoplastics and rubber).

- can be cleaned with methyl ethyl ketone (MEK).

- prevents compression resistance. The injection moulding material spreads better in the cavities.

- is an economic alternative to expensive sinter plates.

- can be cleaned with methyl ethyl ketone (MEK).

Delivery forms: Blocks and slabs are available in different wall thicknesses

| Delivery forms |

|---|

| ALWA POR STEEL: 200 x 300 x 20 mm – 120 mm |

| The slab tolerance values are between 0 – 0.6 mm in length, width and thickness. |

| Slabs can be sawn to any required size. |

Technical data ALWA POR STEEL:

| Characteristic | Norm | Unit | Value |

|---|---|---|---|

| Average pore diameter | µ | ~ 14 | |

| Total porosity | % | > 30 | |

| Density | g/cm³ | ~ 4.4 | |

| Hardness (dot-matrix) | DIN 53505 | Shore D | ~ 95 |

| Long-term temperature resistance (mould temperature) | DIN 53462 | °C | ~ 190 |

Please consider the different thermal coefficients of linear expansion if ALWA POR (CHROME) STEEL is screwed on a slab or something is screwed on ALWA POR (CHROME) STEEL (slab, block or mould). Drill larger holes for the screws into the material, so that the different expansion coefficients can level out. Screw connections which are used several times should be equipped with threaded sleeves.