ALWA POR PLASTIC

- Products

- About ALWA

- Customer service

Filter

–

ALWA POR PLASTIC

Here you can see all the advantages of ALWA POR PLASTIC at a glance:

- is made of plastic particles and a resin binder.

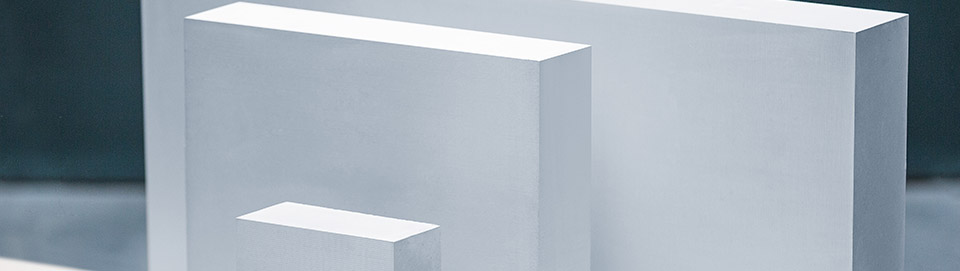

- is porous and produced as a block or slab in our factory in Gronau, Germany.

- is easily machinable.

- is suitable for:

- vacuum clamping technology,

- filter applications,

- aeration of sewage treatment plants,

- air film sliding technology and many other applications.

VERSIONS OF ALWA POR PLASTIC:

| Article | Average pore diameter | Total porosity |

|---|---|---|

| ALWA POR PLASTIC | flexibely adjustable from ~ 8 – 23 µ | depending on the average pore diameter between ~ 30 – 33 % |

Technical data:

| Characteristic | Norm | Unit | Value |

|---|---|---|---|

| Density | g/cm³ | ~ 0,79 | |

| Hardness (dot-matrix) | DIN 53505 | Shore D | (according to the average pore diameter) ~ 75 – 84 |

| E-Module | DIN 53457-B3 | N/m² | 6.98 |

| Long-term temperature resistance (mould temperature) | DIN 53462 | °C | ~ 65 |

Delivery forms: Blocks and slabs (customised dimensions)

For flat and longer slabs, we recommend storing the slabs vertically or place a weight on top if horizontally stored to avoid bending of the slabs and thus the bi-metal effect.

Note the different coefficients of thermal expansion when ALWA POR PLASTIC is screwed to a plate or something on ALWA POR PLASTIC (plate, block or mold). Drill larger holes for the screws in the materials so that the different expansion coefficients can compensate each other. Screw connections that are used several times should be provided with threaded sleeves.