ALWA MOULD D System

Application:

Vacuum thermoforming Indursty

Product number:

SW10000

Attention this product is a bundle!

Please select the quantity you need and then select below the number of components you want or need to buy.

Please select the quantity you need and then select below the number of components you want or need to buy.

Amount needed:

Liter

Corresponds to:

1.7

Volume in kg

Contains:

Component 1: 0.23kg

Component 2: 0.45kg

Aluminum 4065: 1.02kg

Hardening powder: 0.02kg

Fast curing in approx. 50 min.

Fast curing in approx. 50 min.

Good mechanical finishing

Good mechanical finishing

Low linear shrinkage

Low linear shrinkage

Good casting ability

Good casting ability

Post annealing not required

Post annealing not required

Finest impression accuracy

Finest impression accuracy

Casting without air pockets

Casting without air pockets

High heat resistance

High heat resistance

Problem-free pouring of small and large quantities (1 kg - 2500 kg)

Problem-free pouring of small and large quantities (1 kg - 2500 kg)

Product information "ALWA MOULD D System"

ALWA MOULD D System

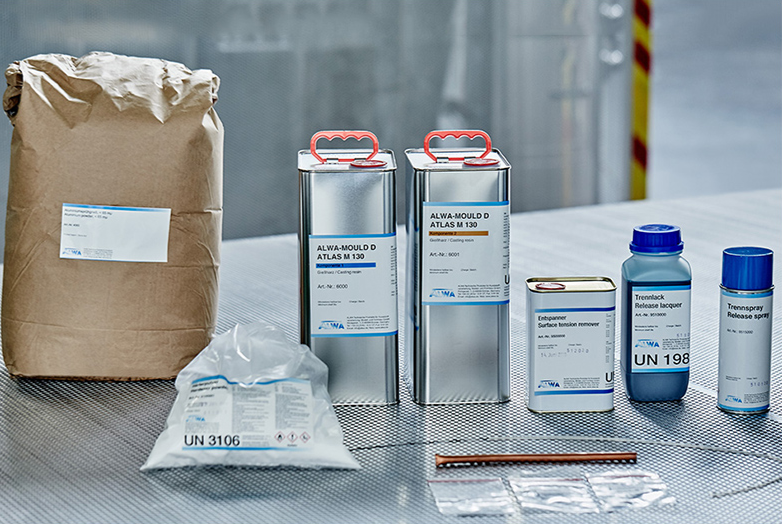

The casting resin system consists of two acrylic resin components and a filler.The rapid curing of the material allows the production of high quality moulds in just one day. The material is very easy to cast, so moulds of any size can be produced, such as bathtubs, boats, etc. (<1 kg - 2500 kg).

Compared to other materials (e.g. glass fiber reinforced plastic), the system is more temperature resistant, allows potting without air bubbles and does not require post-curing. In addition, the moulds can be machined (2. e. drilling, milling, grinding, planing, sawing, turning, etc.).

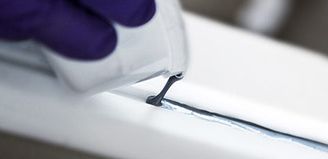

ALWA MOULD D moulds can be modified with repair putty so that appropriate views can be created at an early stage of a new design process and prototypes can be examined at short notice.

| Application: | Bath tubs, shower trays, Vacuum thermoforming |

|---|

Working steps

| Step 1 |

Step 2 |

Step 3 |

Step 4 |

Step 5 |

|---|---|---|---|---|

| 40 % resin components,

mixing ratio: component 1 : component 2 1 : 2 |

Stir in 60 % filler,

mixing ratio: resin : aluminium spray grit 1 : 1,5 |

Vent 1 – 2 hrs. temperature must be between 19 °C – 22 °C | Stir in 3 % hardener powder | casting |

Aids

| Product |

art. no. |

|---|---|

| ALWA ACRYLIC SEALER | art. no. 9535000 |

| ALWA SURFACE TENSION REMOVER | art. no. 9500000 |

| ALWA RELEASE LACQUER | art. no. 9510000 |

| ALWA RELEASE SPRAY | art. no. 9515000 |

| ALWA REPAIR FILLER | art. no. 3050001 |

| ALWA PU FOAM, comp. A | art. no. 9700005 |

| ALWA PU FOAM, comp. B | art. no. 9701006 |

| SILICONE TUBES | art. no. 9205000 |

| STEEL WIRES | art. no. 9211000 |

| ALUMINIUM PERFORATED STEEL | art. no. 9213000 |

Stirrer and drill

| Special Mixers |

|

|---|---|

| up to 1 litre | art. no . 9110000 |

| up to 10 litres | art. no . 9120000 |

| up to 25 litres | art. no . 9130000 |

| up to 75 litres | art. no . 9140000 |

| Drills |

|

|---|---|

| 0,6 x 30 x 60 mm | art. no . 9006000 |

| 0,8 x 60 x 100 mm | art. no . 9008000 |

| 1,0 x 60 x 100 mm | art. no . 9010000 |

| 1,5 x 110 x 150 mm | art. no . 9015000 |

Downloads

Product brochure:

CASTING RESIN FOR THE THERMOFORMING PROCESS ALWA MOULD D

Calculation of a batch quantity:

ALWA MOULD D

Success story:

VST WORKS

Success story:

GWK KUHLMANN

Success story:

DEALS & WHEELS

All advantages at a glance

ALWA MOULD D molds Are suitable up to a temperature range of 135 °C, short-time loads up to 180 °C Are possible taking into account the lower compressive strength of the mold due to the temperature. To control the temperature of the mold during the production process, copper tubes or heating elements can be fixed to the model.To ensure an equal coefficient of thermal expansion, only aluminum parts and aluminum perforated plates should be fixed in the casting box as reinforcing material and then encapsulated with casting resin. Steel wires with silicone tubing can be fixed in the model, eliminating the need for time-consuming vacuum drilling on the mold.

| property | unit | value | |

|---|---|---|---|

| Temperature resistance | °C | 135 | |

| Pot life | min | ~ 17 - 20 | |

| Reaction temperature | °C | 120 - 130 | |

| Hardness | Shore D | ~D86 | |

| Compressive strength at RT 20°C / 100°C | DIN 53454 | kN/cm² | 8 - 9 / 7 - 8 |

| impact strength | DIN 53453 | J/n (kJ/m²) | 3400 (3.5) |

| Viscosity of the mixture | mPas | ~7,000 | |

| Specific Density | kg/l | 1.7 | |

| Heat conductivity | DIN 1341 | kcal/hm°C | ~1 (~0.86) |

| Linear shrinkage after curing (test specimen 500x100x25mm) | % | ~±0.1 | |

| Vicat softening temperature | DIN 53460 | °C | 180 |

| Storage stability at 16°C to 22°C | months | ~18 | |

| Coefficient of thermal expansion | DIN 53752 | 10⁻⁶*K⁻¹ | 45 |

We are here for you!

Phone: +49 2562 98157

E-Mail: info@alwa.de

ContactMonday to Thursday

8 am - 5 pm

Friday

8 am - 2 pm