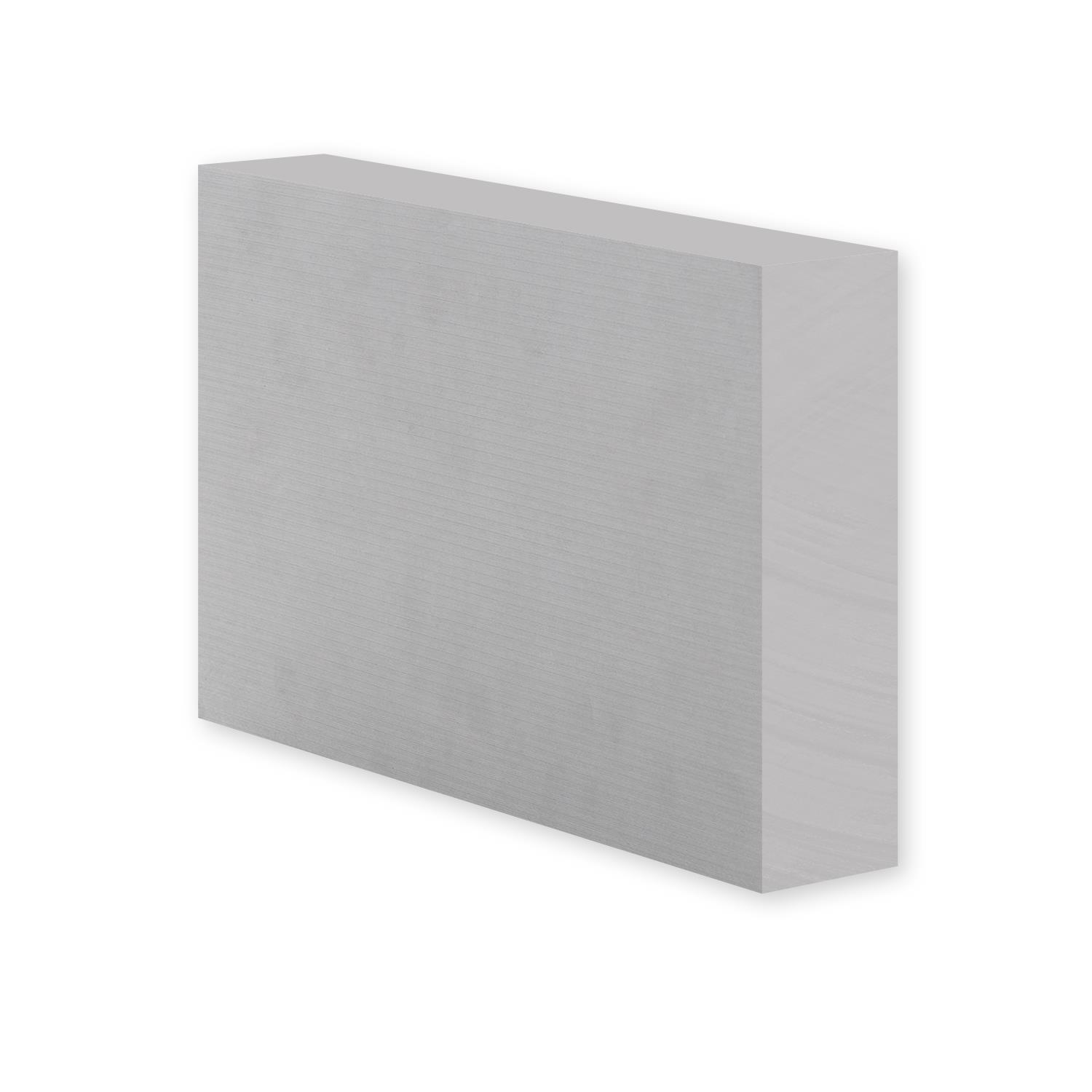

ALWA POR ALUMINIUM 1 (700 x 600 x 40 mm)

Application:

Product number:

1118072

Product information "ALWA POR ALUMINIUM 1 (700 x 600 x 40 mm)"

ALWA POR ALUMINIUM 1 (700 x 600 x 40 mm)

ALWA POR ALUMINIUM

Here you can see all the advantages of ALWA POR ALUMINIUM at a glance:

- is made of aluminium and a resin binder.

- is porous and is produced as a block or slab in our factory in Gronau, Germany.

- has a surface structure from very smooth to good depending on the pore size and is characterized by a good porosity.

- is easily machinable and can be polished to a shiny surface.

- is particularly suitable for thermoforming and other vacuum processing, and is also suitable for

- hot steam or water steam processing (EPS/EPE/EPP),

- vacuum clamping and gripper technology,

- filter applications,

- air film sliding technology,

- aeration of aquaria, fish ponds and sewage treatment plants,

- foundry and many other applications.

Delivery forms: Blocks and slabs are available in different wall thicknesses:

| ALWA POR ALUMINIUM | small slabs | big slabs |

|---|---|---|

| ALWA POR ALUMINIUM 1 | 200 x 300 x 20 mm – 150 mm | 1200 x 600 x 20 mm – 110 mm |

| ALWA POR ALUMINIUM 2 | 200 x 300 x 20 mm – 170 mm | 1200 x 600 x 20 mm – 130 mm |

| ALWA POR ALUMINIUM 3 | 200 x 300 x 20 mm – 160 mm | 1200 x 600 x 20 mm – 120 mm |

| ALWA POR ALUMINIUM 4 | 200 x 300 x 20 mm – 140 mm | 1200 x 600 x 20 mm – 120 mm |

| ALWA POR ALUMINIUM 5 | 200 x 300 x 20 mm – 220 mm | 1200 x 600 x 20 mm – 110 mm |

The slab tolerance values are between 0 – 0.6 mm in length, width and thickness.

Slabs can be sawn to any required size.

Non-binding milling data:

R10 ball nose ~ 7000 RPM feeding speed ~ 5000 mm/min.

R 4 ball nose ~ 7000 RPM feeding speed ~ 3500 mm/min.

Technical data:

| Characteristic | Norm | Unit | Value |

|---|---|---|---|

| ALWA POR ALUMINIUM 1 very smooth surface ALWA POR ALUMINIUM 2 smooth surface ALWA POR ALUMINIUM 3 good surface (NEW) ALWA POR ALUMINIUM 4 good surface ALWA POR ALUMINIUM 5 good surface | Average pore diameter | µ µ µ µ µ | ~ 6 – 9 ~ 12 – 15 ~ 30 ~ 50 – 53 ~> 60 |

| Total porosity ALWA POR ALUMINIUM 1, 2 and 4 | % | ~ 17 – 20 | |

| Total porosity ALWA POR ALUMINIUM 3 and 5 | % | ~ 30 | |

| Density | g/cm³ | ~ 1.8 | |

| Hardness (dot-matrix) | DIN 53505 | Shore D | ~ 87 |

| Flexural strength | DIN 53452 | M P A | ~ 35 |

| E-Module | DIN 53457-B3 | M P A | ~ 9600 |

| Impact strength | DIN 53453 | kJ/m² | ~ 11 |

| Thermal coefficient of linear expansion | DIN 53752 | °C-1 x 10-6 | ~ 27,2 |

| Thermal conductivity | DIN 52612 | Wm-1 °C-1 | ~ 19 |

| Long-term temperature resistance (mould temperature) | DIN 53462 | °C | ~ 190 |

| Glas transition temperature (TG) | °C | ~ 300 |

Please consider the different thermal coefficients of linear expansion if ALWA POR ALUMINIUM is screwed on a slab or something is screwed on ALWA POR ALUMINIUM (slab, block or mould). Drill larger holes for the screws into the material, so that the different expansion coefficients can level out. Screw connections which are used several times should be equipped with threaded sleeves.

Downloads

Product brochure: POROUS SLABS AND BLOCKS ALWA POR

Success Story: LEBOEUF

| Application: | Aeration for aquariums, fish ponds and sewage treatment plants, Air film control technology, Decor and design, Drainage and filter systems, Foundries, Heat exchanger and cooling, Intake molds and devices, Pneumatic transport, Shock absorption, Sleeve assembly in roller printing units, Steam and hot air processes, Vacuum clamping technology, Vacuum thermoforming |

|---|

We are here for you!

Phone: +49 2562 98157

E-Mail: info@alwa.de

ContactMonday to Thursday

8 am - 5 pm

Friday

8 am - 2 pm