Creating a Unilever heart mould

Manufacturing a Unilever Heart Shape

Welcome to our guide on manufacturing a Unilever heart shape using our

advanced ALWA MOULD D casting resin. In this process, we delve into the world

of 3D printing and resin casting to provide you with a precise and versatile

solution.

Step 1: 3D Printing

Our journey begins with a powerful 3D printer that allows the customer to create a negative pattern. This pattern serves as the foundation for our casting process. 3D printing provides us with the precision and flexibility to effortlessly realize complex designs.

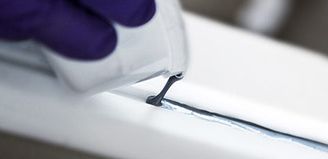

Step 2: The ALWA MOULD D Casting Resin

Once the customer has created the negative pattern, our main actor comes into play: the ALWA MOULD D casting resin. This innovative product is poured into the negative pattern and solidifies in approximately 20 minutes.

Step 3: Creating a New Mould

While the ALWA MOULD D resin cures in the mold, it takes on the shape of the negative pattern. The result is a positive, a perfect replica of our original design.

Step 4: Ready for Thermoforming

The product is a positive ready for thermoforming. This straightforward process makes it an ideal choice for both beginners and experienced model and mold makers.

Manufacturing a Unilever heart shape with ALWA MOULD D casting resin is not just a project, but a testament to the power of innovation and creativity. So, what are you waiting for? Dive into the world of 3D printing and resin casting and discover the endless possibilities that await you.