Innovation & Sustainability at ALWA

Despite all its adverse circumstances, the year 2020 has been a good starting point for an increased sustainable change at ALWA. We have set ourselves ambitious goals.

Highlights

- Recycling: Against the backdrop of further EU directives to be expected, new paths have to be followed in Germany as well, to ensure higher raw material yield in recycling processes. In this context, we talked to Ms Holtkamp and Mr Nolden of the ZENIT GmbH Enterprise Europe Network NRW and discussed possibilities to take back products from our clients, to develop a secondary production by recycling.

- Green raw materials: Through further research and development we want to increase our sustainability, as we strive to use of green raw materials parallel to our current input materials.

- Company energy (e. thermostats): Electric thermostats are assisting in energy conservation and provide higher comfort. We can configure at what time each heater starts to heat. For example, the office is already heated at the begin of work and cools down to economical 16 degrees Celsius after the end of working hours.

- Company energy (annealing oven)

- Procuring and choice of raw materials

- Company energy (photovoltaics): It is currently tested to what extend a photovoltaic system can be installed at ALWA, to reduce our CO2 emissions.

- Company energy (LED illumination): The hall lighting at the location in Gronau has been adjusted to modern, sustainable standards. With the new LED-lightings we can reach a theoretical energy saving of over 50%, with significantly higher light output and thus reduce the CO2-emissions.

- Company energy (water dispenser): If an employee on average drinks one liter of water per working day, a company with 100 employees could reduce the annual waste by 506 kg with the installation of a water dispenser. A water dispenser reduces the costs, waste and CO2-emissions resulting from the purchase, transport, and storage of bottles. It is equipped with energy saving cooling technology and a natural cooling agent.

- Mobility (video conferencing): On 18 February 2020, the ecological Verkehrsclub Deutschland (VCD) presented a study that found, that nationwide 3 million tons of greenhouse gases could be saved per year, by an increased use of video conferences instead of business travels after the end of the covid pandemic. ALWA is internationally active and could not only contribute to the reduction of greenhouse gases, but also give our clients direct recommendations for current challenges and thus strengthen the customer loyalty, through video conferences.

- Mobility (electric mobility): Electric mobility is a substantial element for environmentally friendly traffic, since e-cars drive without emissions, quiet, and often less expensive than comparable cars with a combustion engine. This year, we further promoted the issue of e-mobility. Moreover, we will provide our own vehicle fleet, employees, and clients the possibility to load electric vehicles at corresponding charging poles.

- Sustainable personnel policy (smoke-free site at ALWA): Our Gronau facility is smoke-free since 1 January 2020. The objective is to have more people live a smoke-free and thus healthier life. We already achieved the goal of a non-smoking company in the course of the year.

-

Social responsibility:

- Honorary lecturer at the University of Paderborn

- Disinfection agents

- Fundraising campaigns (Lichtblicke Seniorenhilfe & Lichtblicke Kinder)

Renewable raw materials for casting resins – shown by the example of methyl methacrylate (MMA)

ALWA asks the question concerning the sustainability of our products and processes. We want to address this issue early on by searching for renewable raw materials for our resins, to identify chances, risks and to conceptualize an appropriate long-term strategy.

Out of the „12 principles of Green Chemistry“,1 the principle of using renewable raw materials is, as a producer of cast resins, primarily applicable for our products. The possibilities will be explained in the example of methyl methacrylate (MMA), a very important component of casting resins.

There are two ways to increase the sustainability of resins containing MMA by using renewable or at least partially renewable raw materials:

- Production of MMA from renewable raw material (biomass, wood, etc.)

- Production of methyl acrylate (MA) from renewable raw material

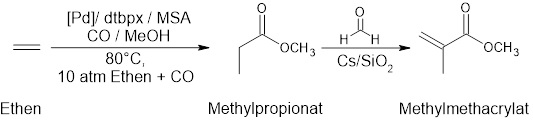

Note on 1.: A relatively new process called „alpha“ process has been commercialized by Lucite2 in 2008. Here, ethylene, carbon monoxide and methanol are converted to methyl propionate using palladium catalysis. In the next step, a cesium catalyzed aldol reaction with formaldehyde gives the MMA.

Figure 1 Lucites „Alpha“ process for the production of MMA

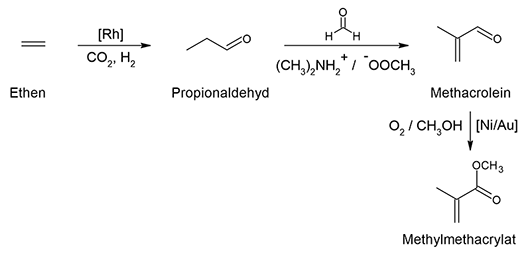

An alternative method has been patented by Evonik Industries in 2014. Like the “alpha” process, the „LiMA“ process starts with ethylene. It is hydroformylated with synthesis gas to propionaldehyde.3 Next, an aldol reaction with formaldehyde catalyzed by dimethylamine and acetic acid yields methacrolein. In the final step, methacrolein is converted to MMA by an oxidative esterification using Nickel and Gold catalysis.4

Figure 2 Evoniks „LiMA“ process for the production of MMA

Both processes still use conventional resources but have the potential to switch to renewable raw materials. Ethylene can be produced out of bio-based naphtha and ethanol. Carbon monoxide and methanol can both be acquired by a gasification of biomass.5

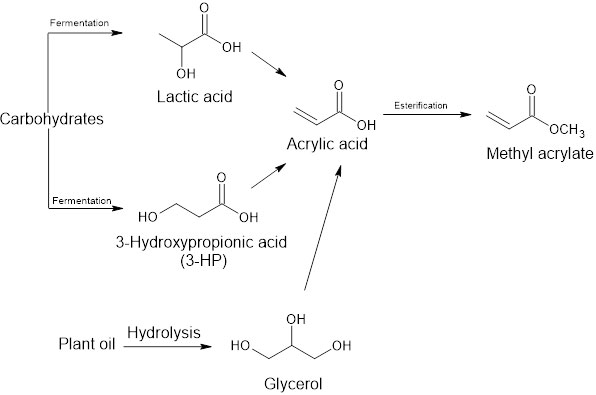

Note on 2.: Because these processes are dependent on the producers and out of our control, we also took a deeper look in another option, that allows us to perform experiments already. We examined biorefinery products and identified lactic acid, 3-hydroxypropionic acid and glycerol as possible raw materials for the synthesis of methyl acrylate. Lactic acid and 3-HP are accessible by fermentation of carbohydrates and glycerol forms in the hydrolysis of triglycerides like oils and fats. These raw materials can be converted catalytically to form acrylic acid.6–8 Methyl acrylate can be obtained through esterification of the acrylic acid with methanol.

Over the last years, industrial testing plants showed that the production of acrylic acid out of carbohydrates, biomass and glycerol is generally possible. However, in many cases the projects were not continued, often because of economic reasons like glycerol costs. 9

Figure 3 Renewable routes for the production of methyl acrylate

It remains open to what extent MMA can be replaced by MA, without affecting the mechanical properties. In general, the missing methyl group lets PMA become softer and more flexible than PMMA. It is unclear whether this effect will occur in combination with the other components in our resins as well. We will analyze this experimentally.

Finally, it remains to be seen, if the need for biomass and bio-based ethanol can be fulfilled, especially if other products and processes, will be switched to renewable raw materials as well. The higher amount of required biomass, which in some cases includes corn and sugar, will affect the price and availability of food.

- Anastas, P. T.; Warner, J. C. Green Chemistry: Theory and Practice, Reprint Ed.; Oxford University Press, 2000.

- Darabi Mahboub, M. J.; Dubois, J. L.; Cavani, F.; Rostamizadeh, M.; Patience, G. S. Catalysis for the Synthesis of Methacrylic Acid and Methyl Methacrylate. Chem. Soc. Rev. 2018, 47 (20), 7703–7738. https://doi.org/10.1039/c8cs00117k.

- Jong, E. de; Higson, A.; Walsh, P.; Wellisch, M. Biobased Chemicals - Value Added Products from Biorefineries. A Rep. Prep. IEA Bioenergy-Task 2011, 36.

- Lyu, S.; Wang, T. Efficient Production of Acrylic Acid by Dehydration of Lactic Acid over BaSO4 with Crystal Defects. RSC Adv. 2017, 7 (17), 10278–10286. https://doi.org/10.1039/c6ra28429a.

- Benn, G. P.; Craciun, L.; Dewing, J. R.; Peer, W. J.; Schriver, G. W.; Siebenhaar, B.; Siegrist, U. Preparation of Acrylic Acid Derivatives from Alpha or Beta-Hydroxy Carboxylic Acids. WO2005095320A1, 2005.

- Ahmad, M. Y.; Basir, N. I.; Abdullah, A. Z. A Review on One-Pot Synthesis of Acrylic Acid from Glycerol on Bi-Functional Catalysts. J. Ind. Eng. Chem. 2021, 93, 216–227. https://doi.org/10.1016/j.jiec.2020.09.026.

- Rodríguez, D. M. Biobased acrylic acid https://biorrefineria.blogspot.com/2021/05/Biobased-acrylic-acid.html (accessed Oct 19, 2021).